Wacker Neuson expands compaction telematics

08 July 2020

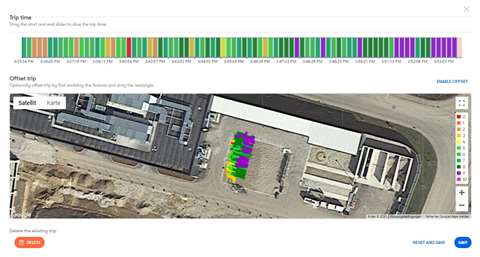

German manufacturer Wacker Neuson has made its telematics solution, Compamatic, available on all of its heavy-duty reversible vibratory plates and a number of its remote-controlled models.

The company says Compamatic makes the process of compaction traceable and allows for documented quality control, with data on where compaction had been carried out and to what degree.

The system allows project managers to, for example, plan asphalt deliveries without having to visit sites for quality control purposes.

Supervisors can remotely check on daily planned compaction

Latest News