How these companies are leading a resurgence for RT cranes

15 November 2021

The range of projects that use rough terrain cranes is vast. With new models recently launched and the market showing signs of resurgence, these cranes are ready for action. Niamh Marriott reports.

Terex Cranes announced its latest rough terrain crane, the TRT 35. It expands the Terex TRT rough terrain offering following the launch of the TRT 80 (which had an 80 tonne capacity) and the TRT 90 (90 tonne capacity) earlier in 2021.

Terex’s new New TRT 35

Terex’s new New TRT 35

The counterweight of the TRT 80 was designed so that it can be modularly assembled, meaning its overall weight can be reduced when needed, while the TRT 90 has the same self-removable ballast as its predecessor (the RT 90), eliminating the need for auxiliary cranes. An important feature of both cranes was that the machine width was only 3 metres – allowing the cranes to be easily transported and manoeuvred, even in congested job sites and other confined areas.

The 35 tonne capacity crane has a 30.1 metre synchronised four-section telescopic boom. Maximum tip height with extensions is 40.1 metres. Its carrier is 2.5 metres wide to help when manoeuvring around narrow or confined areas, the company said. It also has four steering modes.

Power comes from a 4 cylinder Cummins diesel engine, which has an eco mode function. Versions are available to meet different exhaust emission requirements around the world.

It has permanent four wheel drive and a powershift transmission with two modes for different operator driving styles. Manual mode offers three speeds forward and three speeds reverse while the automatic mode has five forward gears and three in reverse.

The crane features the Terex Operating System (TEOS) which the company said improves safety, usability, efficiency of navigation, operation and information flow.

As well as the TEOS control system, the TRT cranes are designed with compact dimensions, proportional telescopic boom, full power and come equipped for the T-Link telematics platform allowing geo localisation and remote diagnostics. Terex T-Link telematics, which provides customers with real time information on the performance of their crane comes as standard on the TRT 35, along with LED lights.

Telematics and real-time data

Further options include; an 8 metre lattice type side-stowable jib, radio remote control, auxiliary winch with same performance as the standard winch, outrigger control from the carrier, anemometer, and cameras that display on the 10 inch touchscreen so the operator can watch directly from the TEOS display.

Guillaume Bertrand, RT sales manager at Terex Cranes, says, “The addition of the TRT 35 will enhance an already significant product range offered by Terex Rough Terrain Cranes, meeting both market and customers’ needs for a flexible yet durable off-road crane.

“As well as the intuitive TEOS control system, the TRT cranes have compact dimensions, proportional telescopic boom, full power and come equipped for T-Link telematics platform allowing geo localisation and remote diagnostics.”

Liebherr safety as standard

The higher tonne capacity classes of this crane type seem to dominate the current market. Liebherr offers a series of RT cranes in the 90 tonne and 100 tonne classes, notably the LRT 1090-2.1 and LRT 1100-2.1. Both models have an outrigger monitoring system as standard. The support status, on tyres or outriggers, is detected automatically and saved to the crane controller. The attachment of the ballast to the turntable and the installation of the optional double folding jib including its angle adjustment are also recorded and monitored.

liebherr’s LRT 1100-2.1

liebherr’s LRT 1100-2.1

The VarioBase variable support base, developed by Liebherr, makes an important contribution to safety, the company said. Safety is also enhanced by providing greater comfort for the crane operator. For example, the crane cabin is 220 millimetres wider than other standard cabins on the market. It can be tilted backwards to provide greater comfort when hoisting loads to great heights. Clear, self-explanatory controls make the crane easy to handle.

The 100 tonne LRT 1100-2.1 has a 50 metre telescopic boom with Liebherr’s Telematik telescoping system where the various telescoping sections can be extended independently with a single cylinder and then pinned to the telescopic section above. A maximum of 14 tonnes of counterweights helps ensure high stability.

The capacity of the LRT 1100-2.1 is around 15 per cent higher than that of the 90 tonne model which features 12 tonnes of counterweight. The LRT 1090-2.1 features a 47 metre telescopic boom and its telescoping system consists of a two-stage hydraulic cylinder with a rope extension mechanism.

Link-Belt’s latest rough terrain model

Brian Elkins, Link-Belt rough terrain product manager, says, “RTs are used in almost any lifting application – everything from general construction to plant work, bridge work, steel erection, and everything in between. Right now, the busiest markets are in the 80 to 120 ton (72 to 108 tonnes) range. The 100 to 110 ton class is probably the most popular. Demand to work at radius, as well as up and over, continues to require higher capacity cranes.”

Link-Belt’s latest rough terrain model, the 85|RT, falls into this popular category at 85 tons (75 tonnes). “The 85|RT was the next logical choice and really an easy decision for introduction following the 120|RT and 100|RT design. It transports under 47,627 kilogrammes with full counterweight and under 39,000 kilogrammes with no counterweight,” says Elkins.

Link-Belt’s cab design for its rough terrain cranes has been well received in the field

Link-Belt’s cab design for its rough terrain cranes has been well received in the field

It has a five-section formed boom that has a range of 11.6 to 43.3 metres. It uses Link-Belt’s V-CALC (Variable Confined Area Lifting Capacities) system, which the company says offers an infinite amount of outrigger configurations and provides real-time 360 degree charts. The system has already been used on a range of construction projects.

“Once the outriggers are set, Link-Belt’s Pulse 2.0 system can indicate the crane’s available capacity. The system then previews the operator’s real-time capacities given the crane’s current configuration as well as the next five radii for a set boom angle,” says Elkins.

Power is from a 270 horsepower (201 kilowatt) Cummins Tier 4F QSB 6.7 diesel engine and includes a new drive train.

Link-Belt’s rough terrain cranes

Operator comfort and safety is also being considered in the latest designs for rough terrain cranes. “Link-Belt’s cab design has been well received in the field, both in terms of visibility, operator comfort and intuitive design,” comments Elkins. “All electrical components coming into the cab are bulk headed for “plug and play” assembly, an ergonomic seat with electronic joystick and single axis controllers provide comfortable operator’s station, and cab tilt of 20 degrees keep line of sight easy for any jobsite.”

“Textured and slip-resistant paint on all walking surfaces improves durability and footing,” he continues. “Centralised electrical locations, remote mounted filters, and easy-access fluid checks simplifies routine maintenance and service.”

Manitowoc

John Bair, Manitowoc product manager says, “We do see the capacity requirements of RTs increasing and that is why we have focused on providing new models in these segments. Over the last five years we have introduced five new rough terrain models and four of those models have been 80 US ton capacity and above. Currently, the 100 US ton class is the highest volume class in the rough terrain product range today. Over the last decade or so the market has shifted from the 60 to 70 US ton class being the most popular models in rental fleets to the 100 US ton class. Much of this is due to fleet owners wanting to maximise versatility in their fleet. RTs are used for a wide array of applications ranging from general construction, bridge and highway to the energy sector and having flexibility in reach and capacity is pivotal to ensure high utilisation.”

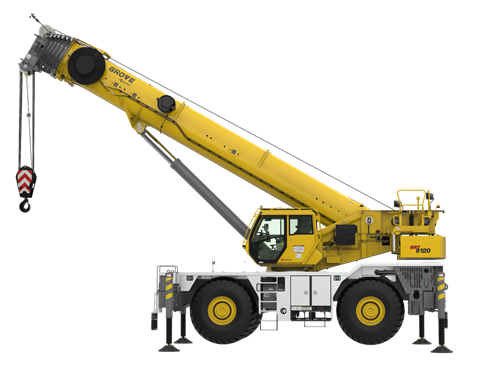

Grove’s two most recent rough terrain introductions are the GRT9165 and the GRT8120. “With the GRT9165, we introduced the longest boom and strongest capacities you’ll find on a three axle rough terrain carrier,” Bair says.

The new model has a 205 foot (62.5 metre) main boom and 165 US ton (150 tonne) rating. With any large RT, a key topic is transportability. “With the GRT9165 we went with a new three axle carrier design that allowed us to reduce the overall height of the crane to 12.4 feet (3.78 metres) making it much easier to transport from jobsite to jobsite.”

The GRT9165 has removable front and rear outrigger boxes and hydraulically removable counterweight that can all be self-rigged without the need of an assist crane, saving both time and cost to any project.

“With the GRT8120 we wanted to enter this 120 US ton class with a truly unique offering that provided unmatched reach but in a very compact package.” The GRT8120 has a 7-section, 197 foot (60 metre) main boom. “It provides the reach of RT cranes found in the 150 ton range

Manitowoc’s GRT8120 provides the reach of RT cranes typically found in the 150 US ton and above class

Manitowoc’s GRT8120 provides the reach of RT cranes typically found in the 150 US ton and above class

, but with the compact dimensions of RT cranes typically found in the 80 to 100 US ton class.”

Also featured on the GRT8120 is the Maxbase variable outrigger positioning system to make it easier to set up on congested jobsites, while also allowing for increased capacities when compared to the standard 360 degree load charts. “These features make the GRT8120 perfect for refineries, utilities and general construction applications where set up space is limited,” Bair explains.

“A new feature on the GRT9165 is the ability to reverse the driving and steering controls when driving with the boom positioned over the rear of the carrier. Before this, when driving with the boom positioned over the rear of the carrier, the operator would have do everything opposite to what he wanted to do. Now with the new Driving Orientation Switch you no longer have to do this, making operation much easier,” Bair continues.

Customers are always looking for longer booms with increased capacities. As a manufacturer Grove says it is constantly looking for ways to provide this. “One way we have done this with our new GRT9165 and GRT8120 models is utilising a laser-hybrid weld process during the manufacturing of the booms,” a spokesperson says.

Laser-hybrid welding combines a traditional arc weld with a laser weld acting simultaneously in the welding zone. It can reduce the weight in the boom by up to 500 pounds (226 kg) depending on the length of the boom, Grove claims. Those weight savings in the boom can then be used to improve the load charts.

Tadano launches the GR-1300XL

Manufacturer Tadano launched the GR-1300XL-4 for North American market in March 2021. It is the first 130 US ton capacity rough terrain crane the company has made. As a high capacity model it is larger so emphasis in the design was put on easier transportability by trailer. The idea is that it can be moved using two trailers of a size and type owned by most of its customers.

In May 2021Tadano expanded its crane offering in Europe by launching three new rough terrain crane models. The GR-700EX-4, GR-900EX-4 and GR-1000EX-4 are long-boom designs with high lift capacities reaching 70, 90 and 100 tonnes, respectively.

Typical applications for rough terrain cranes are narrow, safety-conscious sites such as oil refineries and chemical plants. Larger models are also increasingly being used as support cranes for renewable energy sources such as wind power generation construction. In addition to improving crane performance, Tadano is working to develop environmentally sound products with lower carbon dioxide emissions.

A reason for the trend towards higher capacity models, especially seen in the USA, is an increase in the size of the modules (suspended loads) in factories. Another reason is to improve safety by having a performance margin instead of always being up to the wire on capacity. Tadano expects to see a similar trend in other regions, including Asia and the Middle East. As these cranes become larger gross vehicle weight and transportability will become bigger challenges.