The road to carbon neutral concrete

13 April 2021

Dr Andrew Minson, GCCA

Dr Andrew Minson, GCCA

Concrete is the most widely used material after water and has played a vital role in the world around us since ancient times. It is essential to the modern world, providing the infrastructure that connects individuals and enables society to thrive – such as roads, bridges, homes, schools, hospitals, as well as food, water and energy supplies.

It is so widely used because of its many performance benefits – including its strength, durability, fire resistance and weather resilience, as well as its local availability, abundance and versatility.

It also has less well known attributes, such as thermal mass, which can reduce the energy needs of buildings, and it reabsorbs carbon from the atmosphere to act as a carbon sink. Structures made from concrete can last for many generations and can even be repurposed or recycled in a circular economy context.

Concrete’s climate challenge

While concrete’s properties, and its versatility, enables designers to deliver high performing projects that meet the needs of clients, most people are now aware it also presents us with a significant climate challenge.

Concrete underpins our built environment and is so widely used in buildings and infrastructure that it is responsible for around 7% of global CO2 emissions. These arise from the manufacture of cement – the key binding ingredient – from the energy used to heat the limestone to the required high temperatures and the CO2 emitted as it changes its chemical composition.

Reducing these CO2 emissions is our industry’s key challenge. Ensuring that we create a sustainable environment for the world to thrive in is essential. That is why in September 2020, 40 of the world’s leading cement and concrete producers, represented by the GCCA, announced a global climate ambition: to produce carbon neutral concrete by 2050, in line with global climate targets.

This is the first time the global industry has made such a commitment and represents a significant milestone. It builds on decades of emissions reductions progress – our independently verified data shows that the cement industry has made a 19.2% reduction in emissions per tonne of cementitious material since 1990. But we still have a long way to go.

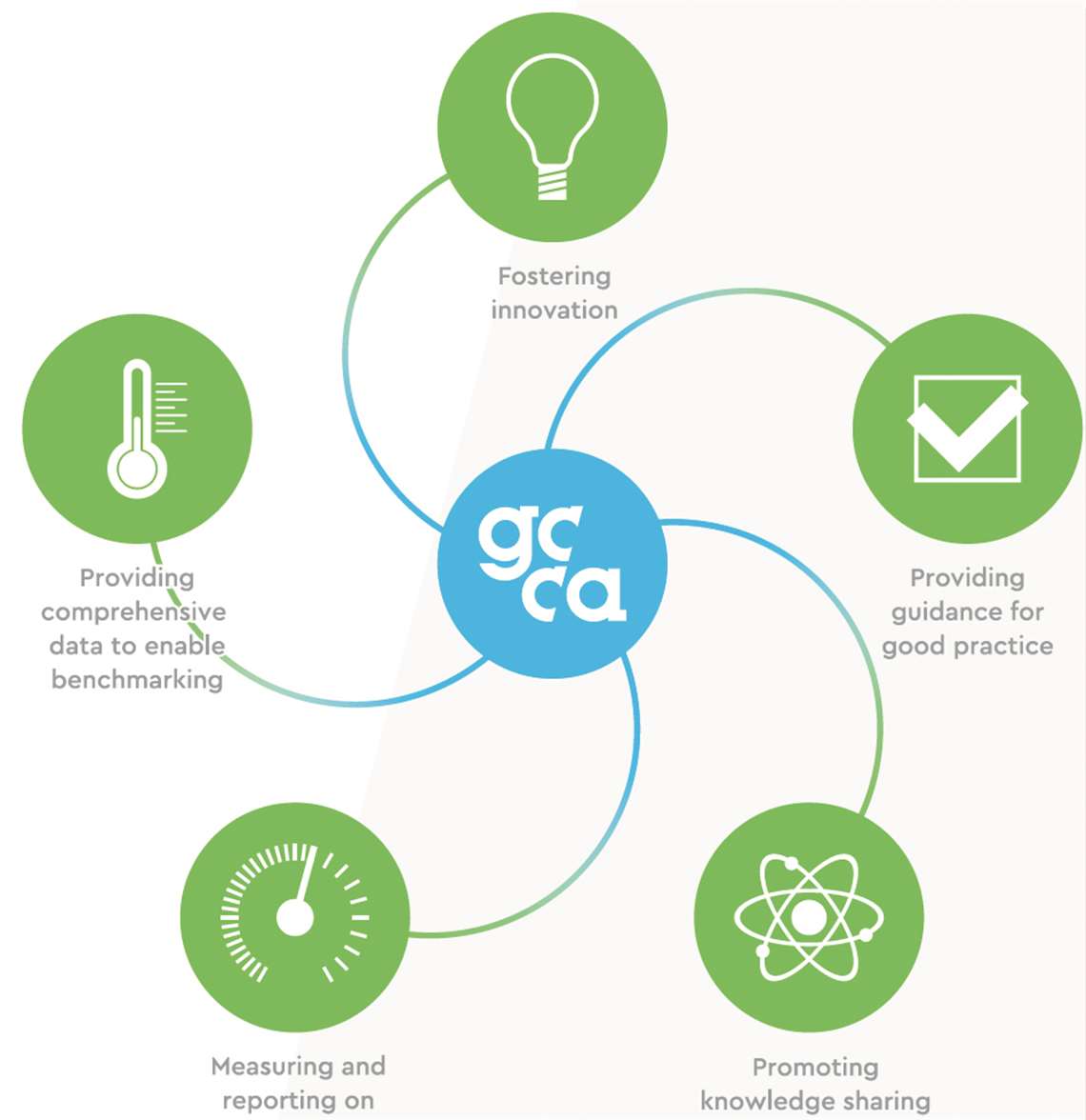

This sustainability journey is one of the GCCA’s main objectives – bringing together the industry and wider stakeholders at a global level to ensure we meet our climate targets. Work is in full swing on developing our 2050 Roadmap to Carbon Neutral Concrete, which will set out the pathway, levers and milestones that will need to be activated to meet this ambitious goal, and will be published at the end of the year.

Cutting concrete emissions is a key goal of the GCCA

Cutting concrete emissions is a key goal of the GCCA

The necessary levers range right across the value chain – from production processes, ingredients and enhanced technologies during the cement manufacture stage, to construction and use such as minimising waste, maximising efficiency, building in circularity and fully unlocking concrete’s performance potential.

Innovation will play a critical role, which is why our Innovandi Global Cement and Concrete Research Network was formed to bring together leading industry organisations with scientific institutions from around the world to work together to develop research and critical solutions to address the climate challenge.

Policies in place

Developing a roadmap for such a wide-reaching material that is used in all parts of society requires input at multiple levels – from policymakers, investors, designers, end users and governments. At the manufacturing stage it means, for example, ensuring established policies that enable co-processing of society’s waste in cement kilns are adopted more widely.

At the procurement stage, this means fair assessment policies that ensure full accounting of carbon footprints across the whole lifecycle of a project, and are inclusive of carbon impacts from materials due to land use and end of life combustion.

Concrete is being used by designers and builders today to deliver a sustainable built environment, and the determined sustainability journey we are on will ensure that concrete plays a crucial part in building the sustainable world of tomorrow.