CoreHaus opens first modular construction plant

03 August 2021

Specialist housing provider begins full production of steel-framed modular homes at its new UK facility

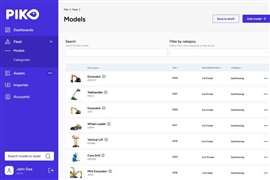

The opening of the CoreHaus manufacturing facility was attended by (left to right) Scott Bibby of CoreHaus; Gaynor Tennant from Offsite Alliance; and Mark Farmer, CEO of Cast Consultancy and adviser to the UK Government on MMC.

The opening of the CoreHaus manufacturing facility was attended by (left to right) Scott Bibby of CoreHaus; Gaynor Tennant from Offsite Alliance; and Mark Farmer, CEO of Cast Consultancy and adviser to the UK Government on MMC.

UK modular housing manufacturer CoreHaus has opened its first manufacturing facility, and begun full production of its steel-framed modular homes.

One of the newest modular housebuilders in the country, the company is a joint venture firm made up of Carlton & Co Group and public procurement specialist Fusion21.

Corehaus said its new 1850m2 facility will use modern methods of construction (MMC) to more quickly build houses that offer lower energy bills.

The opening of the new facility in County Durham in the north east of England, was attended by key industry guests, including Mark Farmer, CEO of Cast Consultancy and an advisor to the UK Government.

Speaking at the event, Farmer said, “I am really excited to be here today. I get to open a lot of factories but this one feels very different to me.

“CoreHaus is an important step towards modernising construction. The product is very different to many modular homes; it’s a hybrid modular home with its pod and panel approach.”

Scott Bibby, CoreHaus managing director, said, “Our light gauge steel-frame system ensures that CoreHaus can be used in both urban and rural locations with elevation treatments tailored to suit each setting, providing almost unlimited design potential. The standardised modular core means the solution can be configured for homes of almost any size.”

With an existing order book valued at around £6 million (€7.1 million), the manufacturing plant will initially supply units to regional housebuilder Homes by Carlton, as well as a national social enterprise charity.

According to Bibby, the demand for housing in the UK is currently outstripping supply.

As a result, the next five years will see the company ramp up its annual production to around 1,000 units a year, with its staff numbers anticipated to grow to around 300 people.

Bibby said, “We know the housing sector wants something that’s both affordable and incorporates high-quality design within a modular frame.

“We are already in discussions with several regional and national housing associations interested in working with our product.”