Details on the Deere-Deutz deal

24 February 2021

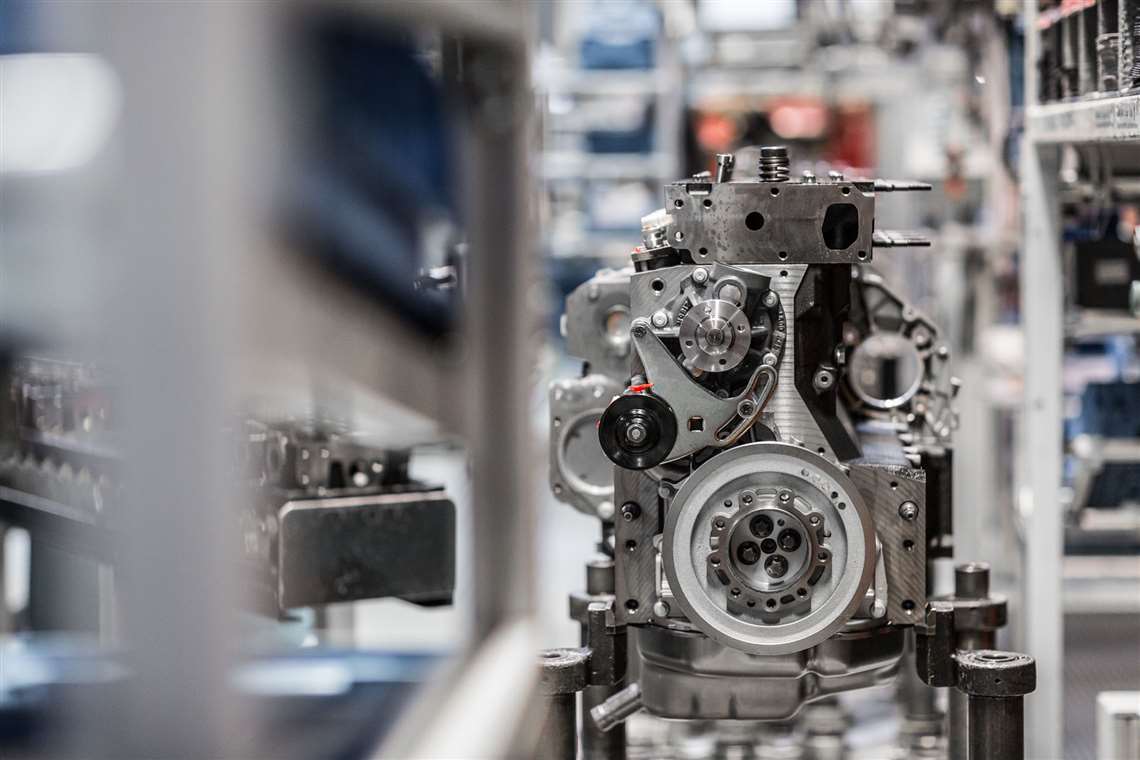

John Deere Power Systems and Deutz AG are collaborating to design a new off-highway diesel engine that will be available in ratings up to 130 kW (174 hp).

John Deere Power Systems and Deutz AG are collaborating to design a new off-highway diesel engine that will be available in ratings up to 130 kW (174 hp).

By Mike Brezonick

When in early December, John Deere Power Systems and Deutz announced one of the most interesting, and possibly most significant, engine agreements within recent memory, there wasn’t a lot of specific information available.

The basic facts were head-snapping enough – that two global diesel engine heavyweights, competitors in many segments of the industry, were teaming up to “jointly develop and source components for a low horsepower range engine up to 130 kW (174 hp).”

Now, with the assistance of Nick Block, director, Global Marketing & Sales at John Deere Power Systems and Dr. Markus Müller, senior vice president, Product Development & Technical Customer Support at Deutz AG, more details on the fascinating engine development are available, with perspectives from each manufacturer.

HOW LONG HAVE YOU BEEN CONSIDERING THIS KIND OF LINK-UP WITH ANOTHER MANUFACTURER AND WHAT WAS THE MOTIVATION BEHIND IT?

Block: We have been exploring options to collaborate with another manufacturer for a lower horsepower engine for more than a year. Our experience in collaborating with Liebherr for the new 18.0 L engine demonstrated the impact of successful collaboration in design and manufacturing of innovative power systems. The motivation for this collaboration in particular was to replicate that success in the low horsepower range.

Müller: The initial talks with Deere started almost a year ago.

Deutz, as one of the last independent engine manufacturers, has significant experience in the successful collaboration of engine developments with other engine manufacturer or large equipment OEMs across the globe. This approach enables us to benefit from larger economies of scale.

WHAT DID EACH COMPANY SEE IN THE OTHER THAT MADE IT AN ATTRACTIVE PARTNER?

Block: Deutz, like John Deere Power Systems, is one of the world’s leading manufacturers of innovative drive systems. Collaborating with Deutz allows us to utilize their expertise in developing small, cost-competitive engines while leveraging a common supply base and the scale of the joint volume between the two companies.

In seeking collaboration, John Deere stakeholders assessed our goals and what we ultimately wanted to achieve. We selected Deutz out of a variety of capable partners based on its experience with small- and medium-sized engines.

Müller: John Deere and Deutz are both recognized experts in designing and manufacturing innovative power systems. As such, the synergies gained from this collaboration in design, qualification and sourcing are significant.

In addition, the combined volumes of both companies ensure competitiveness for the benefit for our customers.

ACCORDING TO THE ANNOUNCEMENT, BOTH COMPANIES WILL CODEVELOP AN ENGINE TO BE MANUFACTURED, BRANDED AND SOLD BY EACH COMPANY. WHAT’S THE ADVANTAGE OF THAT AS OPPOSED TO ONE COMPANY BUILDING THE ENGINE TO BE SOLD BY BOTH COMPANIES?

Block: The advantage of co-sourcing and co-developing the engine hardware is that it allows us additional internal resources to focus on evolving and refining our proprietary technologies (including software, controls, certifications, etc.) that we will utilize on John Deere products.

As we transition to our Smart Industrial strategy (see August 2020 Diesel Progress), we are steadfastly committed to the continuous renewal of our engine product line. This collaboration enables us to accomplish that while leveraging our manufacturing to apply differentiated requirements needed to meet our internal applications and OEM needs.

Müller: This is a development cooperation, the partners will be independently responsible for the production, sales and marketing of their respective versions.

Also, the partners will customize their own brand engines for their respective customers. This leads to an increased overall availability of engine variants for the end customer.

DO YOU HAVE A TIMETABLE AS TO WHEN YOU WILL BEGIN DESIGNING THE ENGINE AND WILL THE DESIGN FUNCTIONS TAKE PLACE AT BOTH COMPANIES?

Müller: The proof of concept was completed months ago, and the industrialization has been recently started. We combine the best know-how and resources from both partners. The overall project management will essentially be handled by Deutz.

FAST FACTS

■ While the joint announcement referred to a “low horsepower range engine up to 130 kW,” it will in fact be a single engine model, with multiple available ratings topping out at 130 kW. “This collaboration is for one engine,” Block said, “allowing us to deliver a new family of products.”

■ Both companies will sell the engines globally through their individual distribution networks. “Engine distribution will be done independently by each company,” Block said. “John Deere plans to offer its engine globally through its equipment product lines and OEM distribution channels.”

■ Neither company would confirm when the engines will go into production or what manufacturing locations each would use. “The engine design enables us to produce at all our worldwide manufacturing locations,” Müller said. “This approach allows us to produce close to the customer as well as cost efficient.”

■ Müller said that in the first year of market availability, “we expect a low four-digit number of engines to be built under the Deutz brand.”

This story first appeared in the February issue of Diesel Progress. For a free subscription, click here.