VR and AR: Visualising the future of construction

25 June 2019

Construction Industry commentators have been discussing the benefits of virtual reality (VR) and augmented reality (AR) for many years. The benefits in terms of training, marketing and planning are obvious, but they also have the ability to improve efficiency and worker safety by providing insights that established technologies cannot offer.

To avoid any confusion, it is worth explaining the difference between the two terms. VR refers to the creation of an entirely simulated environment and has a relatively long history in the construction history, particularly in demonstrating how any project will look once completed. AR involves superimposing computer-generated images and information on real-world images.

AR is an excellent tool for communicating complex information, as it adds context by overlaying data and other information on the real world for the end user. Variations, known as assisted reality and mixed reality are also being developed, and all these technologies can incorporate other sensory information, including sounds.

Research from Global Market Insights indicates that the operator training market will be worth over €17.79 billion by 2025. This growth has been partially attributed to recent improvements in VR technology, meaning traditional fixed display technology is being replaced with head mounted display (HMD) simulator training modules.

The pros and cons of VR for construction industry

VR can be used to simulate real world situations and scenarios, and to give workers hands-on experience and training prior to entering a jobsite. “This helps to educate and plan, which improves overall productivity and the safety of workers on site,” said Scott Crozier, general manager of Trimble’s Civil Engineering and Construction Division. He added that it is currently used for sharing designs and building information modelling (BIM) data with the client, “which helps put the information into a ‘language’ that the client can more easily understand.”

The technology also allows remote operation. For instance, at Bauma China in November, Sany demonstrated its unmanned driving VR technology for excavators. Operators will be able to control machinery and carry out digging work from thousands of miles away. Shi Xiangxing, head of Sany’s Excavator Electric Control Institute, said that this technology means operators will no longer need to be present in difficult weather conditions, commenting, “He or she could sit comfortably at his office to see the big screen and check the real-time monitoring.

“All the big data, including the machine performance, work efficiency, etc, will be delivered to the monitoring centre.”

In the longer-term, he is confident that VR will be used for 3D imaging and long-distance wireless transmission.

Martin Lehner, CEO of Wacker Neuson group, said the company is currently working on a virtual variant configuration. He explained that customers will be able to view different variants before purchasing in the future, allowing them to configure their chosen machine individually. Wacker Neuson already relies on VR in product development.

“It allows our customers to test the products virtually at an early stage of development and give their important feedback directly to our engineers. This makes development more agile, faster and more efficient,” he said.

Another use of this technology is through simulators which can be used to train operators before their equipment even arrives. Drew Carruthers, product line manager for construction products at CM Labs Simulations, directs the development of his firm’s Vortex construction equipment simulators, which are designed to cut costs and increase productivity. They are used for mobile or tower cranes, backhoes, excavators and wheeled loaders.

“The growth potential for this technology in construction is huge, as cost of technology comes down,” said Carruthers. “Mixed reality tools, which merge real and virtual environments, will likely be the next frontier for safety, operations, communications and inspections in construction.”

Training Technology for contractors

Canadian company CM Labs, developer of Vortex training has partnered with Antycip Simulation, a leading provider of professional-grade simulation software, to establish local presence in Europe.

CM now maintains branches of Antycip offices in the UK, France, and Italy, facilitating hands-on demonstrations of simulation-based learning solutions at all three locations.

Through its presence at these Antycip offices, CM Labs now provides local solution set-up, training, and support to clients in countries throughout Europe, including Austria, Belgium, Denmark, Finland, Germany, Iceland, Luxembourg, The Netherlands, Norway, Spain, Sweden, and Switzerland.

Netherlands-based rental company Riwal has introduced virtual reality simulators to increase safety and efficiency when working at height.

The platform and telehandler rental specialist said the simulators provide additional training for scissor lift and boom lift operators, in a variety of high-risk construction industry scenarios.

Each device comes equipped with a working basket for operators to stand in, virtual reality goggles and a control panel with joysticks and switches that mimic those on real machines.

Virtual reality training simulators create a controlled environment for operators to train in, thereby lowering personal safety risks and saving significant amounts of money lost to damages of equipment and infrastructure.

The company said the technology also provides operators with opportunities to refresh their training, particularly if an operator has not worked with a machine for some time.

Pedro Torres, Riwal COO, said, “Safety is of paramount importance to us, and we will continue to seek new opportunities and innovations to make working at height as safe as possible.” He added, “We are confident that the VR simulators will reduce the cost of renting and operating machines for our customers.”

Mobile applications

UK-based Avontus Software has launched its new virtual reality app, Scaffold VR, which works in conjunction with its Scaffold Designer software.

Scaffold VR provides a walk-through of Scaffold Designer-created designs, and it enables users to view and share these designs in a 3D virtual environment. Co-workers and customers can use the app to view drawings on their office workstations as well as on their mobile devices in the field, providing an interactive experience that clearly demonstrates what a user is offering customers, or showing scaffolders the scaffold they will build.

Avontus’ Scaffold Designer enables users to create and print traditional 2D and 3D engineered drawings. With the free app, anyone with a Windows desktop, a smartphone or a tablet can view and rotate those 3D scaffold drawings. But with a smartphone and the Scaffold VR Cardboard Viewer, they can walk through and virtually experience the scaffolding, both from afar and up close. This provides Scaffold VR users with the opportunity to catch mistakes before they become reality, which helps to ensure a scaffold is designed correctly and avoids costly rework from delays and overruns.

Once a bid is won and users are ready to finalise the scaffolding, they can virtually travel through the structure and identify potential hazards (such as obstructions), which helps them create a safe work plan. Users can thoroughly familiarise crews with the project, so that they can safely hit the ground running. Then, at the job site, crews can access 2D and 3D drawings on any mobile device, or inspect the job virtually through a smartphone and a VR viewer.

Julian Priebe, head of construction trade press at Liebherr, said that good VR solutions with exact position tracking and attractive visual representation still require extensive hardware equipment, such as a gaming laptop or external sensors. “In order to reach a wider circle of users, an easy-to-use, mobile and qualitative solution would have to be developed,” he added.

The augmented reality on site

AR has become more widely used since it became available on smartphones, while smart helmets and glasses are taking its usage to a new level. There seems to be a consensus that AR is still at the early stages of being used in the construction industry, but that it will become an integral part of the design and construction process in the near future.

This technology can help mechanics or engineers trying to identify problems with complex pieces of machinery, including through 3D modelling of blueprints. They can view it through their phone’s screen, with information hovering over the screen’s overlay in real time. Companies are now using AR to demonstrate products and product options to potential customers through the use of different scenarios.

Trimble uses its SiteVision AR application to aid communication between the field and office, by allowing staff in both locations to view the same plans. One of the main applications is in construction inspection, where a design can be loaded and placed to scale. An inspector or site foreman can then use SiteVision to confirm the progress, work completed, or to identify any errors on site. This could be used for utilities, grading, road and earthworks. Crozier said, “It has the potential to reduce change orders by identifying errors early, improve productivity and reduce the cost of a project.”

In November, Trimble demonstrated the use of the Microsoft HoloLens (a VR headset with transparent lenses for AR) for prefabricated rebar. “With this technology, two people can view and collaborate around a piece of prefabricated rebar and view the design model at the same time. The HoloLens scans the environment constantly, and differences to design can be detected,” said Crozier.

Now Trimble has developed the next stage in this technology. The Trimble XR10 with HoloLens 2 fits onto a hard hat and enables workers in safety-controlled environments to access holographic information on the worksite.

This innovation promises greater accessibility to 3D models for front-line workers, and Trimble says broad adoption of mixed-reality for jobsite activities could improve efficiency, productivity and quality of work.

Trimble said that the continued development of its cloud-based collaboration platform, Trimble Connect for HoloLens, will enable workers in the field to get more value from constructible 3D models and transform daily work, such as assembly and inspections.

Remote maintenance

AR scenarios and data goggles with a camera will be used to perform remote maintenance on machines in the future, according to Wacker Neuson. The service technician onsite with the machine will be instructed by a remotely-located expert. The service technician will share the view of the machine with the expert via the camera, enabling the latter to assess the situation and help find a solution.

The growing use of VR and AR has encouraged construction firms to set up joint ventures with technology specialists to investigate and develop industry solutions. For instance, Liebherr Tower Cranes has entered into a development partnership with the Center for Construction Robotics at RWTH Aachen, to develop construction industry digitalisation from the pre-production phase, throughout the added value chain to the semi-automated construction site.

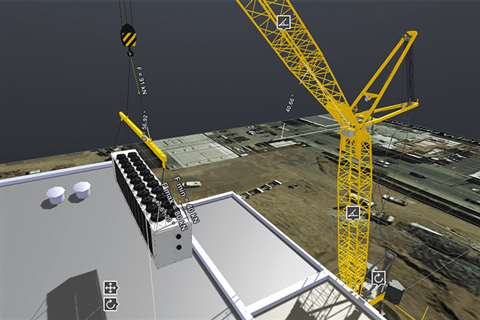

German construction giant Liebherr mainly uses VR in marketing and communication but also in its tower and crawler crane divisions. The Liebherr planning tool Crane Planner 2.0, which is an application for crawler cranes and duty cycle cranes in hoisting operation, allows the construction site to be planned in 3D to make it better understood. Liebherr’s sales team use ‘Crane Planner 2.0’ to present new machines to customers and at trade shows.

Priebe of Liebherr said, “The user can either stand at a virtual planning table and move the machine and simulate the lift, or go directly to the construction site and move freely in space. The understanding of the three-dimensional geometry (sizes, heights and distances of the construction site, the machine and the load) is significantly better than on the display of a flat monitor.”

Duncan McCormick, construction software sales specialist at Topcon, said, “Virtual reality, involving the creation of an entirely artificial world, and augmented reality, where elements of the real world are imposed to create a sort of ‘mixed reality’, are increasingly used in the construction industry. However, it’s the latter that we find most exciting, simply because it has more to offer the end-user.”

As an example, he said that creating a ‘digital twin’ of a real-life project ahead of construction commencing, allows contractors to order all the appropriate materials years in advance. This helps in offering planning security and allows them to get the best possible prices on the market.

“Contractors and project owners have a set amount of time to complete a project and must do it in the most cost-effective and efficient way – augmented reality helps them achieve this.”

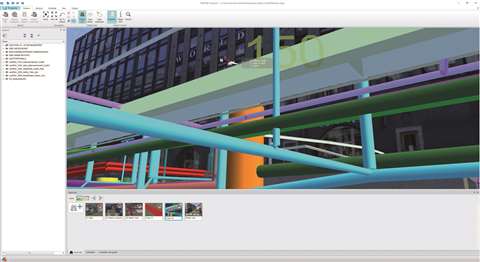

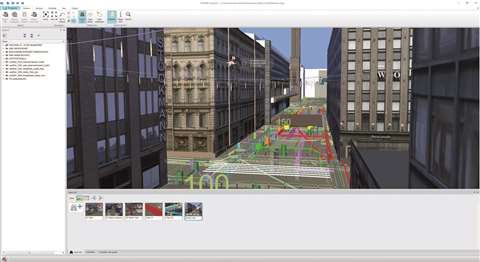

On large infrastructure projects, there are usually various stakeholders with very different objectives. Traditionally, they are all working in isolation, which can result in ‘clashes’ that are costly and time-consuming to rectify. Topcon’s MAGNET Live is a web-based digital platform for reviewing and commenting within a 3D virtual model. This provides project stakeholders with all the critical clash and coordination data in one single model. Furthermore, it allows project owners to better anticipate what might go wrong before construction even begins so they can resolve the issue before it happens in the real world.

Alok Srivastava, director of product management at Topcon Positioning Group, said, “Our product developments continue to pursue workflows that can use AR and VR to improve productivity. We see great opportunities to automate calibration, measurement and positioning of field equipment with the use of object recognition and positioning comparison to design plans.”

Looking to the future, Topcon expects to see currently novel concepts such as CAVE (Computer Assisted Virtual Environment) and Integrated Project Delivery (IPD) become the norm.

CAVE is a groundbreaking immersive virtual reality system that projects a 3D image onto the surfaces of an exhibition space, allowing multiple people to enter this 1:1 scale ‘world’ at one time. Designers can therefore present construction plans in 3D and true-to-life size, as if the project were already built.

The future for VR & AR

There are already countless applications for AR and VR technology in the construction industry and many others are likely to become apparent over time.

One obvious application is to integrate VR technology in BIM to visualise design and BIM information in the field, but this function is still at an early stage of development. However, Crozier said, “As capability and ease-of-use of the technology continue to improve, I believe we’ll see an acceleration in field and office use.”

The opinion of CM Labs Simulations’s Carruthers is that the use of AR will continue to grow, partly because the entry costs are low, in contrast with VR. Mixed reality technology is likely to be embedded into all field survey and machine control offerings before too long.

Srivastava from Topcon said that AR and VR technology, will absolutely enhance productivity and the level of detailed documentation in the field of surveying. These applications and others lead to a more informed team that will make better and quicker decisions.

AR and VR are likely to be used in the future to help overcome the many problems that beset projects at the planning stage. It can be much easier to identify potential difficulties through AR and VR than blueprints and drawings.

With the world’s biggest technology companies investing substantial time and money into VR and AR, and most leading construction companies taking this area seriously, future developments in this sector are likely to happen quickly.