3D Printing: Breakthrough imminent

06 February 2020

Under the admittedly broad term that is ‘construction technology’ some areas are developing faster than others; you’d be hard pressed to find an area that has developed more rapidly in the last few years than 3D printing has.

This technology is currently used by numerous construction original equipment manufacturers (OEMs) to print spare parts and by contractors to print smaller structures but, over the last few years, the technology has quickly evolved.

The possibilities are intriguing – with the construction industry having a skills shortage and many countries around the world in need of more housing, automated 3D printing has the potential to significantly impact the construction industry as a whole.

Dr. Fabian Meyer-Brötz is head of 3D Construction Printing at German-based Peri – the fact that the formwork and scaffolding company even have a head of 3D construction printing is an indication of this sector’s development.

The role was created at the start of 2019 and Meyer-Brötz has been tasked with building up a 3D printing team – Peri has been active in 3D printing for numerous years but see this as a growing sector, as witnessed by the company acquiring a stake in Danish 3D printing firm COBOD in 2018.

Meyer-Brötz comments that this is an emerging market with many questions still to be answered. “I believe that all of the construction industry is still trying to figure out what exactly 3D printing means. That means: what is the right technological approach, what’s the right market, what’s the right region for this? There are a lot of open questions and the core of my job is figuring out where we use this technology.”

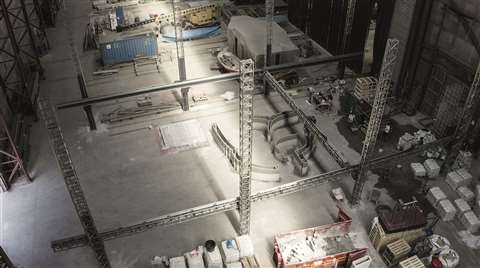

When it comes to 3D printing, there are different types of printers and methods. Two of the more common methods in the construction industry are the robotic arm and the gantry approach: the robotic arm tends to be used on smaller and more intricate designs and the gantry approach to print very large structures.

New technology, new way of working

One of the common misunderstandings about additive manufacturing (AM), the industrial production name for 3D printing, according to Mike Stec, emerging technologies strategy and future solutions manager for Volvo Construction Equipment (Volvo CE) is that it requires a different way of working.

“AM is an entirely new way of working which brings with it new technologies, mindsets, organisational arrangements and competencies – from how to design the software through to logistics, support structures and, of course, health and safety,” comments Stec.

Stec adds that the technology behind 3D printing is not new, but what is new is the rate that the technology is developing. “The technology has been moving fast and shows no signs of slowing down. The growth is partly down to AM’s strong connection with machine learning and AI as well as advanced quality assurance methods and online quality assurance.

“The process and materials are commercial, but the industrial application is what is missing at the moment. But great advances are already underway – specific sectors such as space, aerospace, defense and robotics are making parts that would never have been possible with conventional manufacturing, and construction will follow.”

Volvo CE has been working with Swedish company VBN Component AB since 2013 to evaluate the potential for AM cutting tools to be used in gear machining operations. Initially the performance was equal to traditional manufacturing but tool costs were higher. However, according to Volvo CE, this has now changed with both price and life cycle better than equivalent tools produced using conventional methods.

Antares is a company which performs a number of services, with the supply of products from 3D printing and other processes being one of them. Jens Haehn, managing partner at the company reveals that a common usage of 3D technology is for prototyping in the development phase but that companies using it for the printing of spare parts is becoming increasingly popular – not hurt by the reduction of lead times that the process frequently brings.

Haehn also comments that this is a ‘booming’ sector. “Industrial 3D printing is a booming market, with some of the experts predicting a 25% compound annual growth rate from 2019-2023. The technology is developing rapidly.

“Machine productivity is becoming better every year. For today’s machines, use of multiple lasers compared to a single laser is almost standard. Machine concepts are evolving from a prototyping scope to production scope. Raw material is getting cheaper because of technology developments and rising demand. Integration of post processing (thermal treatment, machining of parts, etc.) is also becoming more automated, hence the entire market is moving quickly.”

Practical uses for 3D Printing

There are examples – most commonly in the Middle East – of whole buildings and other large structures being 3D printed. While these are impressive, and certainly a good way for those in this space to push the boundaries and discover what can be achieved, they are not necessarily cost effective.

Those in construction won’t be printing 3D houses on a commercial scale this year – aside from the regulatory issues, the cost would be prohibitive.

Peri’s Meyer-Brötz agrees that the wider 3D printing community needs to demonstrate the practical benefits of the technology. “There is so much potential in the technology but all of us that are active in 3D printing still have to prove that we can live up to all this potential, to the promises of saving time and money and it really automating processes.”

It is true that automating processes is a key point – with construction experiencing a skills shortage then 3D printing could be one way to address this, with some current 3D printing technology able to be operated by only two people. Of course, for anything to become widely adopted then it also has to save costs and time which, in this instance, has a lot to do with print speed.

“We print with about 25 centimeters a second right now. That’s actually pretty slow for us. The core reason we do it is regulatory issues, we can print a lot faster,” says Meyer-Brötz.

“If you then take into consideration that we’re printing with a two-centimeter layer height, you come to a little bit more than two minutes for one square meter of wall. That’s amazingly quick. If we can utilise that then we can really automate the construction side.”

For contractors, the idea of 3D printed buildings and structures in the future is a real possibility, and there are enticing possibilities for OEMs as well that are more advanced than the printing of spare parts. “For tomorrow, AM could be used for the serial production of suitable parts and performance optimisation for certain machine drive systems,” says Stec from Volvo CE.

“In addition, AM could be used to make advanced components which have heating and cooling needs, lightweight structures and potentially also polymeric larger scale structures such as machine cabs. In fact, in many ways, AM will influence manufacturing across all levels. Certainly, for our customers in construction, we will also see more and more building applications created with AM printing.”

One of the issues for 3D Printing is time: 3D printed buildings need to be lived in for numerous years to convince people of their safety rather than being showpieces for what the technology can do – this will only happen in time.

As the acceptance of 3D printing increases, the technology will also develop further. For a final word on this subject Dr Fabian Meyer-Brötz comments that, “There have been tremendous leaps in the technology. It’s been progressing more quickly than any of us would have hoped for.

“We can impact the way the building industry works and this would be a huge, tremendous change in the way also that people live. It is very exciting to be part of it. It’s only going to work if a lot of other people are also active in the fields of material development, such as designers and architects. It’s not just technology providers like ourselves. It’s a very exciting time.”

Dubai’s 3D dreams

Ambitious 3D Pritning target

Dubai’s 3D Printing Strategy aims to promote the status of the UAE and Dubai as a leading hub of 3D printing technology by the year 2030.

To achieve this ambition Dubai Municipality’s regulations stipulate that every new building in Dubai will be 25% 3D printed by 2025. This regulation came into effect from 2019, starting at 2% of all new buildings, with a gradual increase to the strategic goal of 25%.

The strategy will focus on three main areas: construction, medical products and consumer products.

According to the Dubai Future Foundation, the 3D Printing Strategy aims to reduce construction labour by 70%, costs by 90%, and reduce time by 80%.