Benchmarking

24 April 2008

Skyjack isn't trying to break the mold for self–propelled booms with its new range of machines – the first of which, a 45 ft telescopic model, was launched at the US Rental Show in February. Instead, as Dave Stewart, the manufacturer's vice president of sales and marketing makes clear, the priority was to start with a machine in the “bread and butter” sector of the market – hence the SJ 45T model – and to design it to be easy to use, maintenance friendly and reliable.

This first model was benchmarked against Snorkel, JLG and Genie machines, he says. “We asked around the industry and benchmarked the machine on reliability, its structural integrity and ease of operation.” So, the company is using operating controls and characteristics that are similar to the telescopic boom that Skyjack made in the late 90s, controls that in turn were modelled on the controls used on Snorkel's booms, which, says Mr Stewart, are popular with users.

Physically, “the size of the machine is similar to JLG and Genie, so that it fits everyone's needs domestically and overseas”, he says. As with many Skyjack machines, electronics have been kept to a minimum – there's no computer control system – and the drive system is mechanical axle rather than hydraulic torque hubs. “We believe it's the best way to transfer power”, says Mr Stewart.

Bruce Godkin, the Skyjack design engineer behind the new booms, says the use of the mechanical system will simplify the components used on the unit, in particular at the base of the machine.

Axle suppliers

One issue the company has to address, however, is the smaller supplier base for drive axles. Skyjack president Lloyd Spalding says both Skyjack and Linamar Corp (its parent company) are confident that there will be no supply problems. Linamar is itself a specialist in automotive components, and one could speculate that Skyjack may well be investigating sourcing axles from Linamar. Mr Spalding would not comment.

Benchmarking also involves price, of course. Where will the booms be pitched? “We will be competitive on price [with JLG and Genie]”, says Dave Stewart, “but the goal is not to be 10% cheaper.”

Machines will be out on trial in the coming months and availability of the SJ 45T machine should be later this year. Skyjack also plans a 40 ft telescopic and 60/65 (with jib) telescopics, as well as two 45 ft articulated models, following in 2007. Longer term, probably in late 2007 or 2008, the company will have 80 ft and 120 ft telescopic models (which will require computer control systems that are now under development) as well as a 65 ft articulated model.

Skyjack is starting from scratch, of course, unlike its major competitors, who already have full or semi–complete lines of booms. Neither JLG nor Genie has launched any completely new machines in the past few months, although Genie used the Rental Show to show the first of its new HC (High Capacity) booms (more below) and to &relaunch its 2005 introduction, the Z–135/70, which because of delivery backlogs, hasn't found its way onto the market in the volumes the company had initially planned.

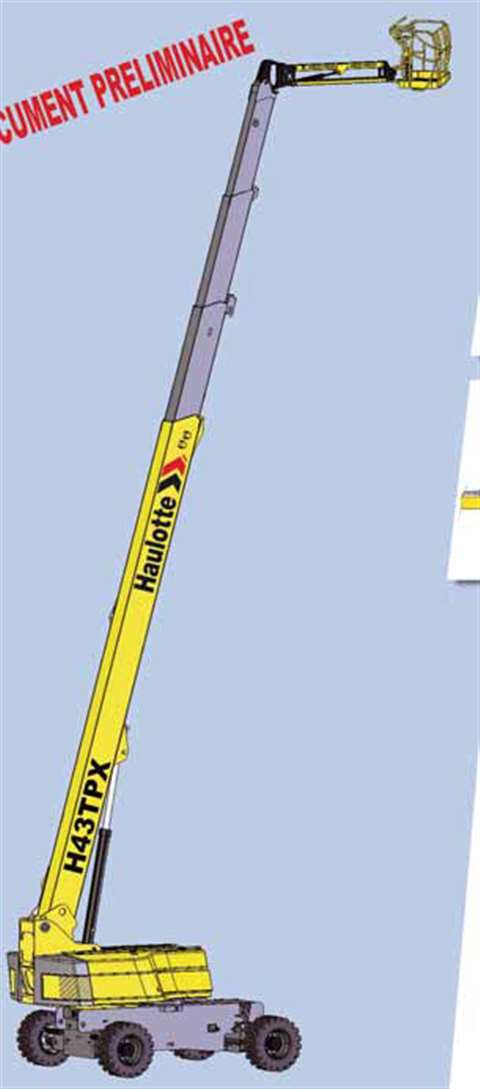

One manufacturer that is being extremely active on the boom side is Haulotte Group. The company launched the 41 m working height, articulated HA 41 PX in the past few months, as well as a completely redesigned 26 m articulated boom, the HA 260 PX. But the focus in the first half of this year will be on the company's largest–ever telescopic boom, the 43 m working height H 43 TPX.

The HA 43, which will offer a maximum outreach of 20 t, weighs 20.4 t (44975 lb) and will use exactly the same chassis and extending axle design as the HA 41 PX, according to Haulotte's product marketing manager, Philippe Luminet; “It's a very robust system. We think it's the best solution for the machine.”

The 41 m unit also uses the same continuous outreach control technology found on the 41 m and 26 m articulated models, reflecting what Mr Luminet describes as the two design priorities for the model; “safety and productivity”. One innovation on the H 43, however, is the use of a 2.2 m jib that rotates both vertically and horizontally. This new &3D' jib design will also eventually be available on Haulotte's other big boom models.

One feature of the H 43 is a dual–capacity cage, with standard 230 kg (507 lb) unrestricted capacity rising to 450 kg (992 lb) with an automatically restricted working envelope. Maximum outreach, for example, falls from around 20 m to closer to 17 m at the higher capacity.

High capacities

Genie is taking this dual capacity option a stage further with the launch at the Rental Show of the first of its new HC (High Capacity) telescopic booms, the S–60 HC, which targets trades such as glazers, bricklayers, and mechanical contractors and film/media users. By using the larger counterweight from the S–65 model and an automatic load sensing and outreach management system, cage capacities on the S–60 HC rise from the standard 500 lb (227 kg) (or 750 lb (272 kg) when a 6 ft (1.8 m) basket is used) to 1250 lbs (567 kg). At this higher capacity the machine's maximum outreach is automatically limited to 40 ft 8 in (12.4 m), which compares to 50 ft 10 in (15.5 m) for the standard model. The HC boom has an unrestricted basket capacity of 750 lb (272 kg).

Phil Harvey, Genie boom product manager, tells Access International that the only structural strengthening required on the HC is a rotator component under the basket: a heavier–duty rotator is now being fitted to all the Genie telescopic booms. The next telescopics to get the HC treatment will be the S–80 and S–85 models, at which time the S–65 jib version will also be made available as an HC model. Ultimately, Genie's 40 ft (12.2 m) and 120 ft (36.6 m) telescopics will also be available in HC configuration.

S–80 redesign

Mr Harvey adds that the launch of the HC versions of the S–80/85 models will coincide with a redesign of the machines, which will feature the fixed axle/counterweight pivot system used on the S–60 model.

How do JLG's boom capacities compare to the new Genie high capacity ratings? Well, JLG offers dual capacity ratings (227 kg (500 lb) and 454 kg (1000 lb)) on its booms as standard in the US and as an option elsewhere. But the technology differs from Genie's in that there is no additional counterweight and the operator has to know the weight in the platform and watch indicator lights in the basket that show allowable platform capacities at any given boom angle and length. There is no automatic cut–out in the event of overload. The higher ratings are mostly offered on non–jib machines, except on JLG's Ultra booms – the telescopic 1200SJP and 1350SJP – which incorporate the 227/454 kg dual capacities as standard and with an automatic envelope control system.

Ron Jackson, JLG product manager, meanwhile tells AI that its next generation of booms will see “more and more development on work station accessories, like the JLG &Sky Welder system – designed to make high–level work easier and smarter by giving the operator purpose–designed and approved tools with known characteristics.”

What else is new or imminent in the self–propelled boom sector? We reported last month on Snorkel's new fixed–axle version of its TB85J telescopic boom. This 4WD/4WS machine uses the same boom as the extendible axle version, but has a redesigned chassis and additional counterweight taking total weight up to 38000 lb (17.2 t). An 85 ft (26 m) articulated boom is also planned for this Autumn.

In Europe, Iteco, although better known for its scissor machines, is extending its articulated boom line beyond the narrow, 11.3 m working height electric model it currently makes. The new IT 150 DE will weigh around 10 t and will provide a maximum working height of 17.3 m and outreach of 10.1 m. With 2WD and powered by a 25 kW diesel engine or by battery, the IT 150 will have stowed dimensions of 7.7 m (with basket) by 2.0 m (H) by 1.8 m (W). Again, this isn't breaking any molds, just extending the envelope a little.