Buyers' privilege

18 March 2008

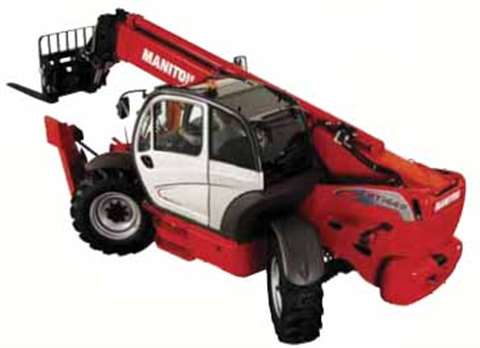

Manitou has two new 4000 kg capacity telehandlers, called Privilege, that are available in ‘rental’ and ‘access’ versions. The 13,5 m lifting height MT 1440 replaces the MT 1435 and the 17,5 m MT 1840 replaces the MT 1740. Both are in production now and available globally.

The French company is offering the handlers with three variations on the standard model. Machines denoted R are for rental and designed for those who “want value for money above all,” said Nick Egan, regional sales manager at Manitou UK, speaking at the official launch of the models in Budapest, Hungary in early September. Rental versions offer fewer options, such as air conditioning, and less power (in the smaller machine).

The A version is for use with an access platform attachment and features a control system offering “total precision” in movement control, as well as radio remote control of telescopic movements. The third variant, denoted EP, allows for retrofitting of the A version control systems.

The Privilege line embodies Manitou's efforts to anticipate the “moving on of European norms; [we are] trying to incorporate as many of these now, “said Manitou president and CEO, Marcel Claude Braud. The company has made safety and driveability major design goals, and operator comfort, “…set the best standards in the world.”

The 10800 kg MT 1440 reaches out to a maximum of 9,38 m with 1500 kg, and out to 5,1 m with its maximum rated load of 4000 kg. The 11380 kg MT 1840 can place 700 kg out to 13,2 m and 4000 kg to 5,0 m.

The two models are very similar dimensionally: overall width is 2,38 and 2,40 m, height is 2,45 and 2,50 m, and overall length is 6,13 and 6,27 m. Turning radius for both is under 4 m.

A Perkins 1104C.44 T engine powers the machines, delivering 74,5 kW in all models excepting the 60 kW in the R version of the MT 1440. A forward and reverse, four-speed torque converter drives the machines up to 25 km/hr, and hydrostatic transmissions are optional from January 2008.

Attachments include side-shifting forks, a 1 m3 pickup bucket, a 0,9 m3earth-moving bucket, and an access work platform (for the “A” version) with a 1000 kg capacity.

Operator comfort

The fully-enclosed cab measures 2m3 and isolates operating noise to 79 dB. It has improved heating and de-misting systems and optional air conditioning.

A dashboard screen displays boom elevation angle and outrigger deployment status, and a “help” screen guides the operator. Another screen presents total hours, incremental elapsed hours, and time remaining until the next major scheduled maintenance. It also displays “maintenance overdue” reminders and fault codes to guide initial trouble-shooting.

Safety features of the models include automatic prevention of “excessive” movements and a parking brake that automatically sets when the transmission is in neutral. Entry of a numeric code to override an integral anti-theft device is necessary to start the machine up.

Features to reduce operating costs include modular boom wear pads, a one-piece boom front end, and a drive unit whose angle drive is internal-there is no prop shaft. Covers protect flex lines, hoses, control valves, and tyre valve stems, and all fluid containers are accessible at the front of the cab. The operator can check the hydraulic fluid level as he climbs into his seat.

“By introducing new [production] technology and efficiencies, the end user price of the product is more-orless the same.”