Disintegration blasting saves the day at the former Rheinenergie power station

04 August 2009

German contractor Richard Liesegang used explosives to solve a challenging problem that could not be dealt with by traditional mechanical demolition techniques during the demolition of the former Rheinenergie power station in Cologne-Niehl. Technical director Marcel Schröder reports

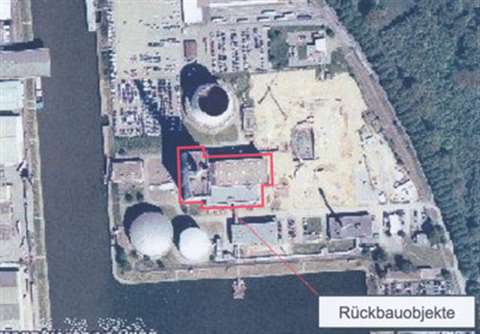

The demolition of the Rheinenergie power station in Cologne-Niehl was considered by the industry as a challenging ‘mega' project, as outlined by the parameters laid down by the invitation to tender issued in early 2007.

The documentation laid down that the contract would be for the deconstruction of two power station boilers with air pre-heaters, each consisting of 2,500 tonnes of steel, some 250 tonnes of insulation and reaching 65 m (214 ft) in height. The job also called for the demolition of the boiler house itself, a structure with a volume of 105,000 m3 (3.4 million ft3) standing 72 m high (236 ft) high, as well as a reinforced steel chimney reaching up 110 m (360 ft) from the roof of the boiler house for a total height of +180 m (+590 ft).

The critical element of the job concerned the core structure of the boiler house, which was characterised by the 13 m (42 ft) tall, 9 by 12 m (30 ft by 40ft) chimney base and a massive 3 m (10 ft) concrete slab at a height of 70 m (230 ft) and by its 1.5-2 m (5-6.5 ft) thick wall plates. Also part of the contract was the demolition of the machine building along with its turbines and the switchgear building.

Quite apart from the physical challenge of the job itself, the nature of the site imposed a number of challenges that had to be taken into account in the planning of the demolition.

A new power station was in operation just 60 m (197 ft) away from the site, which meant that the demolition would have to be vibration-free to avoid affecting the operation of its turbines, thus excluding the use of conventional demolition blasting. The project involved three threshold values for vibration, which could affect the safety programmes of the new facility to the point of shutting it down. In addition, the surrounding port area itself was prone to carry vibration.

Secondly, there had to be minimal dust emissions since the air intake of the new power station faced directly into the wind coming from the demolition site. Finally, the site was close to the fuel oil tank and cooling tower of the new power station.

Initial success - later challenge

The contract for the project was awarded to Becker Umwelttechnik, based in Bottrop, Germany, who used non-explosive techniques on the initial phases of the job. Following demolition of most of the chimney, boiler deconstruction and demolition of adjacent buildings, the centrepiece of the project, the boiler house, still needed to be dealt with.

The original concept called for the reduction of the core structure using a 200 tonne Liebherr HS895 cable dredger with a wrecking ball with a suspension height of 86 m (282 ft). It should be noted that only four of this size are available in Europe. This proved effective when applied to the 0.5 m (1.6 ft) thick walls of the boiler house, but unfortunately the crane was no longer available when work started on the core structure. Attempts to continue demolition using a smaller HS883 (120 tonnes and suspension height of 72 m) met with little success because of the massive nature of the chimney's structure. Complicating factors further was the fact that both boiler house staircases had already been removed.

Another concept involving the use of a 25 tonne hydraulic excavator suspended from a 500 tonne telescopic crane, also proved ineffective.

Expert input

In June 2008 Becker turned to a number of companies affiliated with the Deutscher Abbruchverband e.V, Germany's primary demolition association, to request technical support for the contract.

At that point in time, the exterior walls of the boiler house had been razed to a height of around 40 m (132 ft). However, the core structure remained at its full 70 m height, with the massive 3 m concrete slab of the chimney base in a destabilised position, with rebar jutting out everywhere. The wall plates of the chimney remained untouched and the flue gas pipe, its preformed design unstable to begin with, was still in the slab lead through, along with its coupling to the removed flue gas ducts of the boiler building.

The search for ideas

Through its contact with the demolition association, Richard Liesegang GmbH & Co KG, based in Hürth (and a competitor for the original contract) was able to propose its original concept to deal with the problem. This comprised weakening the concrete structure of the chimney by means of disintegration blasting. This approach actually made it possible to carry out the work with the HS 883, which was still on site.

There was one problem - how to drill holes 70 m up without direct access or even a stable surface to stand on? To overcome this, two Tamrock drilling machines, each weighing 2.7 tonnes, were moved onto movable platforms, each of which had a maximum load of 10 tonnes. Two 250 tonne telescopic cranes then lifted the platforms to their respective work areas. To secure the platforms in place, both were equipped with additional support devices while chemical anchors served as contact points. Tensioning bolts were then used to firmly anchor the platforms in place. This unique approach then allowed the drilling of a total of 360 holes.

Initially 6 kg (13.2 lb) of Eurodyn2000 explosive was used to carry out a test blast on a remaining corner fragment of the concrete slab. The test section with was covered with fleece, netting wire, a light mat for blast protection and 4 cm (1.5 in) rubber curtains, secured with steel cables for extra safety.

The overall positive outcome of the test blast (positive blast result without any measurable vibrations or blast radius) led Liesegang engineers to optimise the parameters for blasting, carrying out two subsequent blasts with 18 and 25 kg (39.6 lb and 55 kg) respectively.

Optimising the timing, quantities and layout of explosives enabled the engineers to fine-tune the outcome of the blast to the point where they could use the third and final blast for actual demolition despite the potential for vibrations.

Both disintegration blasts caused vibrations that remained far below the tolerance limits of the new turbine. Although the chaotic shape of the remaining fragments at the top of the chimney made it impossible to prevent at least some debris falling during the blasting, any debris fell within the danger zone of the site. Demolition work then continued using the HS 883.

Demolition projects that push available resources to their limits should never be approached by concentrating on just one concept.

Blasting technology offers numerous, safe and controlled ways to optimise a demolition project. On this job, it would have been easy to drill blasting holes into the chimney from the top down much earlier into the project, which would have reduced costs and required little more time.