Dubai heights: building the Burj Dubai

15 April 2008

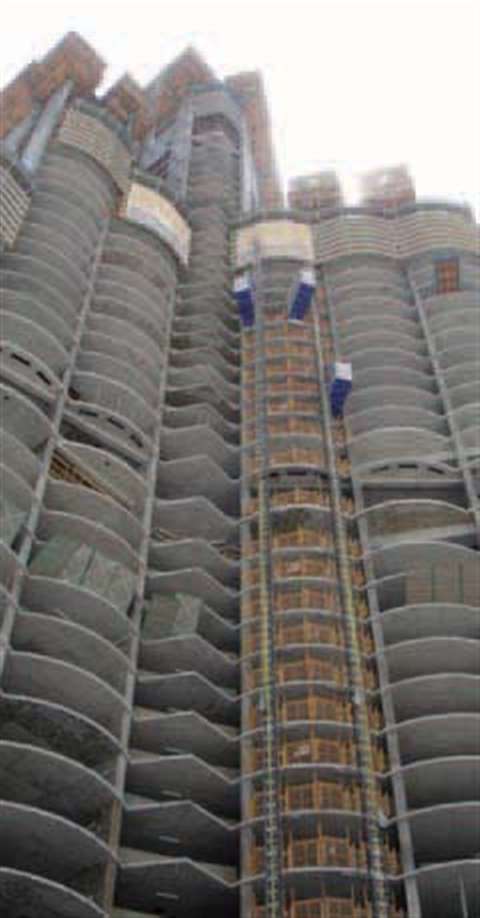

If we're talking about high rise projects, why not start with the highest? The Burj Dubai tower in the United Arab Emirates, currently under construction, will be over 700 m high when it is completed in 2008. Even now, at a height of 330 m, the project is proving a demanding and stimulating one for Czech Republic manufacturer PEGA, who is supplying the construction hoists on the project.

“Almost three years non–stop operation in severe local climate conditions”, says PEGA's industrial hoist director and manager of the Burj Dubai project, Pavel Policar, “Temperatures reaching 53 degrees centigrade, very high humidity, sand storms, fine salt film pollution. And then add into the pot the challenge of unlimited men and materials transportation (4000 people now) and managing traffic peaks.”

These are just some of the challenges facing PEGA, and help explain why the company spent almost two years undertaking “hard preparatory” work before actually starting on the site.

The hoist solution eventually chosen was a combination of large static hoists and smaller ‘jump’ hoists which rise with the building to service the busiest areas. “The concept is four twin hoists (eight cages) on the main building to a height of approximately 400 m in one go”, says Mr Policar, “We are supplying superfast, no–counterweight 3240 BD VFC (variable frequency controlled) hoists (3.2 t capacity, 4 m long cage) running at 100 m/min, full load.” He says this 400 m run is the “longest ever single ride by a [temporary construction] hoist.”

Other ‘fixed’ hoists will be installed at a level of around 400 m, comprising two twin units of the same type serving up to a level of 560 m or 600 m. These are due to be installed later this year. After that, in over a year's time, the final 110 m or so of the tower will be reached by a single twin–cage unit.

In addition to these fixed hoists, PEGA is supplying three single–cage ‘jump’ hoists – a mix of 1 t and2 t units with 2.4 m cage lengths – which service a 90–120 m height and generally cover the section of the tower which is busiest, providing inter–floor transport. “When the building significantly ‘outgrows’ the jump hoist, the hoist is dismounted and transported another 80–120 m higher”, explains Mr Policar.

Quite apart from the challenges of the local conditions of weather, the project presented a considerable analytical challenge. Mr Policar says PEGA drew on a previous study with an Australian contractor on the cost efficiencies of various hoist speeds to arrive at the 100 m/min hoist speed.

The installation required the use of specially reinforced tower sections that can nevertheless still be used with other PEGA sections on other project when the project is complete. The main variable speed hoists themselves are models based on the big hoists that PEGA has developed for the US market and which it has been selling since 2003.

Other non–standard items included a specially designed call/information system in each of the main lifts; “These show on the touch screen panels inside each cabin the position of all the main hoists, their direction of travel up or down, and calls from the floors to be answered.”

PEGA's approximately US$4 million contract is with the Burj Dubai joint venture contractor, comprising Samsung of Korea, Besix of Belgium, and local player Arabtec. Arabtec is playing a major part in the construction of the tower and is also the joint venture partner responsible for erection, operation and maintenance of the hoists. The hoists were supplied directly to the jv by PEGA.

PEGA was helped in the project by having considerable experience in the UAE. Arabtec and other local contractors were operating more than 70 PEGA high–speed hoists in Dubai at the start of the Burj Dubai project.

The massive scale of the project has not allowed PEGA to throw money at the solution. “At each and every moment of the design and conceptual work we were thinking of the final cost of the solution”, he says, “It is easy to come up with an expensive solution…it was our challenge to come up with top technology, clever solutions, and thinking of costs at the same time.”

It is not PEGA's largest ever contract in pure volume terms, says Mr Policar, but it is the company's most important. It's not difficult to see why.