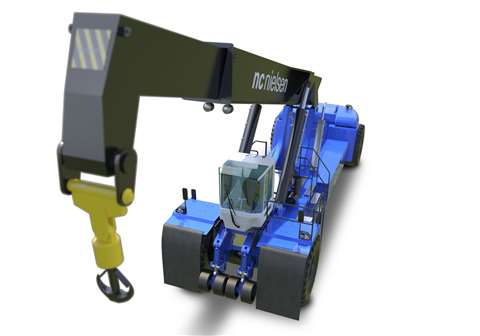

Nielsen reach stacker goes large

08 September 2017

NC Nielsen is developing a heavy duty reach stacker which it says, “will probably be the world’s largest, strongest and most powerful.” The Danish materials handling machine specialist said the new model will lift 152 tonnes on its hook.

The 152 330 TH is being developed in response to an increasing number of enquiries from harbours, shipping companies and wind turbine manufacturers. In addition to high capacity, the requirement is for good manoeuvrability and high efficiency and the ability to travel with load.

A Konecranes 4545 reach stacker is the basis for the new machine. Net weight will be 110 tonnes, and it will be 15 metres long with the boom lowered and 4.90 m wide. Maximum lifting height will be 15.4 m. Modification from the standard machine will include reconfigured geometry, reinforced boom and more counterweight. It will also have larger lifting cylinders and the undercarriage will be pulled in so that the machine can get up close to the load to minimise the lifting radius.

Per Nielsen, N.C. Nielsen technical manager, said, ”Most components of our new reach stacker have been enlarged. It takes numerous calculations, trial assemblies and tests to succeed. However, after a very exciting development process, our engineers managed to find the ’formula’ for our new reach stacker.”

Delivery of the first unit is expected by the end of the year. Production will be at the company’s factory in Balling, Denmark.