Project report: nuclear waste disposal

21 April 2021

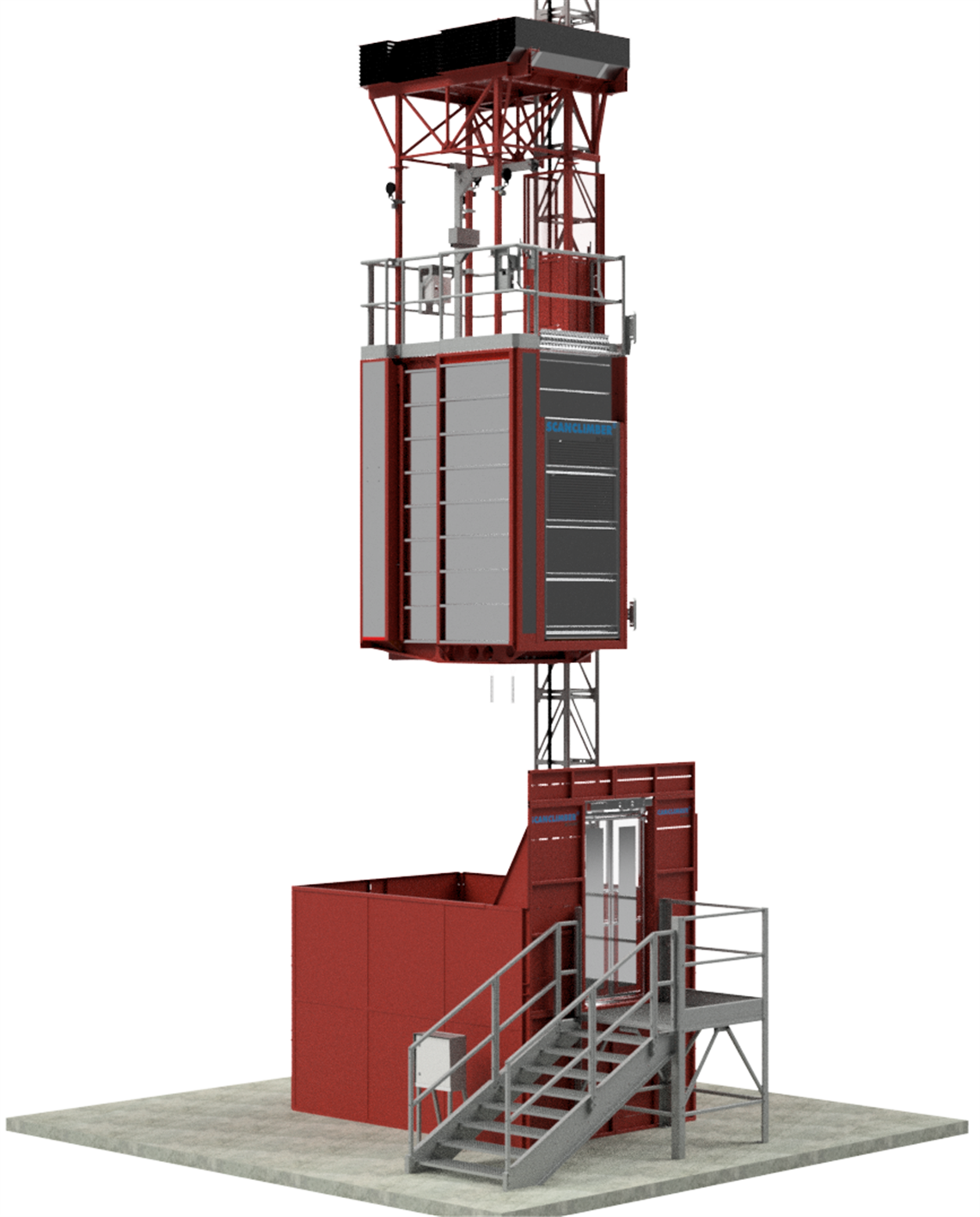

Scanclimber is providing a customised hybrid hoist and work platform in the construction of a unique nuclear waste disposal plant in Finland.

One of the landing stations for the Scanclimber SC2000.

One of the landing stations for the Scanclimber SC2000.

The Onkalo nuclear waste disposal facility under-construction in Olkiluoto, Finland, will be the world’s first permanent geological repository for spent nuclear fuel and high-level radioactive waste.

It is located 500m underground, near Finland’s Olkiluoto Nuclear Power Plant, in Eurajoki, on the west coast of the country.

The catalyst for the project came in 1994 when Finland’s parliament amended its Nuclear Energy Act to specify that all nuclear waste produced in Finland must also be disposed of in the country.

Solid surroundings

In 2000, Olkiluoto was identified as the placement site for what would became a very long-term underground storage facility, thanks to the area being formed of granite bedrock. The municipality of Eurajoki then issued a building permit for the facility in August 2003, and excavation work began in 2004.

The facility was named Onkalo, meaning small cave or cavity, in Finnish and being built and is based about 5km from the main nuclear power plants.

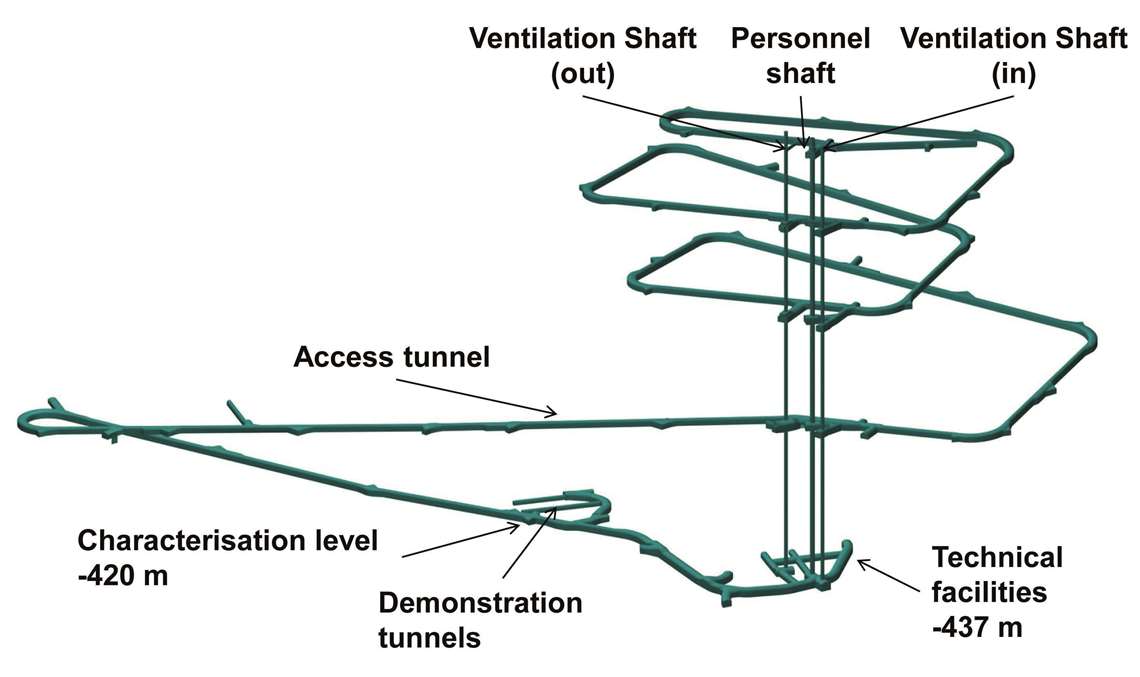

A map of the tunnels that make up the Onkalo nuclear waste disposal facility.

A map of the tunnels that make up the Onkalo nuclear waste disposal facility.

Construction specialist Posiva was chosen to carry out the works ahead of the facility becoming operational in 2023, if all goes to plan. Jarno Säippä is the project manager at Posiva, for the shaft sections of the project, of which there are three: one personnel shaft and two ventilation shafts – one for air coming in and the other for air going out. Säippä’s background is in mining, and he has also been certified an official inspector for Radiation (STUK).

As Säippä explains, the shafts and main tunnels of the site were completed in 2012. The officials gave the permit to build nuclear waste disposal facilities in 2015, and the construction works began in 2016, with the excavating and building of the final nuclear waste placement tunnels.

Commenting on the overall project, Säippä added, “The main challenges of this project is that we are making the world’s first facility of this kind. So, we are setting an example and standard to the rest of the world that nuclear waste can be safely and efficiently disposed of into stable bedrock.”

Longstanding containment

Scanclimber is providing a customised hybrid hoist and work platform in the construction of a unique nuclear waste disposal plant in Finland.

Scanclimber is providing a customised hybrid hoist and work platform in the construction of a unique nuclear waste disposal plant in Finland.

When the facilities are complete, the combined length of the tunnels will be about 50km and will have a total volume of approximately 1.5 million cubic metres. According to the plans, 6,500 tonnes of spent nuclear fuel will be held in the main placement tunnels, which required over 3,000 copper containment capsules to be installed. The entire disposal process will take about 100 years, then the premises will be closed.

The four shafts in the facility are almost 0.5km tall, and a range of work needed to be carried out inside those shafts and on the walls of the shafts. Säippä adds, “Building such a facility is a vast project and demands different and specific kinds of tools and equipment.

For the assembly works inside the personnel shaft, Posiva is using a Scanclimber SC2000 hybrid hoist and work platform. The unit was custom built according to Posiva’s requirements and provides both hoisting and mast climbing work platform capabilities. It is being used to assemble the steel frames of the shaft and carry out HVAC works.

Apart from the challenges of building the shaft, Posiva needed a device to transport people and goods, and this is how the SC2000, with its maximum climbing height of 480m and a load capacity of 480kg, was developed.

The SC2000’s lower deck is based around the idea of a standard hoist with a sliding door and access in and out on any floor. This section of the platform is being used to provide material transportation as required by the project.

The upper deck provides a platform on which personnel can work and access the shaft walls to attach the shaft fittings and install the air conditioning units. From this position the rail guides for what will become the passenger elevator, once construction is completed, are also being put in place.

“Posiva will dismantle the platform at the turn of 2023, and we’ll install a standard counterweighted passenger lift in the shaft,” explains Säippä.

Challenging elements

Preperation and treatment area for nuclear waste capsules.

Preperation and treatment area for nuclear waste capsules.

A challenge at the start of the project was that the remote control’s signal from the platform did not work in a shaft that is almost 500m deep in bedrock. To solve the problem, the radio control was replaced with a cable. Since then there have been no problems, says Säippä.

The work platform’s primary task is to provide the base on which workers can install the steel frames inside the shaft. The frames are 10m high, pre-assembled elements that are lowered down into the shaft using cranes at ground level. During the installation, the steel elements will be bolted together and fixed to the shaft wall.

As the work progresses from the bottom up, the mast of the SC2000 is extended upwards. The mast sections are transported up from the floor of the shaft, using the work platform and installed from there, using Scanclimber’s standard Mast Assembly Crane Arm.

Posiva will then utilise the work platform to install other vital elements in the shaft, like electrical installations, cabling, lighting, piping, safety and emergency equipment. The guide frames for the personnel elevator that will be installed once the shafts have been completed will also then be fixed.

PROJECT TIMELINEPhase 1

|