Surveying: ‘The future is here’

23 August 2017

The days when surveying meant a group of people holding up poles and measuring angles and distances, marking out a site with yet more poles, are long gone, and the techniques used today are becoming more and more sophisticated all the time.

BIM (building information modelling) is a term that was coined only a few short years ago, but is now the key to unlock the data needed on a big project. And the basic information that allows BIM to hold that powerful position, can be sourced easily from so many different places – even the sky, with drones increasingly playing a part.

However, all these new technologies and the possibilities they offer have to be harnessed.

Elżbieta Bieńkowska, EU Commissioner for Internal Market, Industry, Entrepreneurship and SMEs, wrote in the introduction to the Handbook for the Introduction of Building Information Modelling by the European Public Sector, “Similar to other sectors, construction is now seeing its own digital revolution, having previously benefited from only modest productivity improvements.

“Building Information Modelling is being adopted rapidly by different parts of the value chain as a strategic tool to deliver cost savings, productivity and operations efficiencies, improved infrastructure quality and better environmental performance.”

She said, “The future is here, and the moment has now come to build a common European approach for this sector. Both public procurement – which is accountable for a major share of construction expenditure – and policy makers can play a pivotal role to encourage the wider use of BIM in support of innovation and sustainable growth, while actively including our SMEs – and generating better value for money for the European taxpayer.

In the handbook’s executive summary, it says, “The prize is large: if the wider adoption of BIM across Europe delivered 10% savings to the construction sector then an additional €130 billion would be generated for the €1.3 trillion market.

“Even this impact could be small when compared with the potential social and environmental benefits that could be delivered to the climate change and resource efficiency agenda.”

Roads and bridges

One of the leading companies in this area is US-based Bentley Systems. Santanu Das, senior vice president, design modelling, said that one of the biggest advances in information modelling was its use not only in buildings, but also in transportation and heavy civil engineering projects like roads and bridges.

He said there was increased use in brownfield projects.

“Brownfield projects require some sort of starting data,” he said. In the past, 2D drawings were the starting point, then a 3D model.

“One advancement that came out years ago was point clouds – LiDAR,” said Das. “The issue with LiDAR was two big things – it was quite bulky and expensive, you can only do it once every four or five years. The data that are generated would be in the terabytes sometimes and there was nothing really available to process it properly.”

He said a third problem was classification.

“If you took a point cloud, you had no idea what those points meant. A human can figure out, that’s a wall, that’s a column, but in order to do what we call classification, automatically, was impossible.”

He continued, “So what Bentley’s been working on in the past couple years on its BIM platform is reality modelling, and that’s now all a part of our Connect Edition platform.”

Connect Edition converges Bentley’s platform technology to support a hybrid environment across desktop modelling applications, cloud services, on-premise servers, and mobile apps.

“Every single Connect Edition product we have – from Building Designer to OpenPlant to OpenRoads – uses this fundamental datatype that we create from our ContextCapture piece in there.

“That’s one huge advantage that we have for people who want to start off on brownfield projects.”

Bentley can now process this information in the cloud. Das said that with LiDAR and any type of photogrammetry, the number of pictures captured could be astronomical.

“What we doing out with our new ContextCapture in the cloud is that we have the ability to process hundreds of thousands of these pictures in a very, very quick manner, because we’re using the power of multiple servers.

“Then we stream that information as needed to the BIM platform via our ProjectWise.”

With ProjectWise, what Bentley calls i-models can be combined together with other documents into a single package, so that models and associated content can be accessed on an iPad using Bentley mobile apps.

“Reality modelling classification is huge,” said Das. “The other thing that we are finding in information modelling today and the advancement in BIM is the collaboration aspect.”

While people can work together, share data together, Das said there was a problem of a lack of basic terminology of communication.

“So what we have done is to work really hard to come up with a common terminology for all asset class types. So if we’re talking about a beam in a building, or a beam in a plant scenario, it understands what a beam is.”

Some years ago, Bentley introduced i-models, which Das described as “a sort of pdf for the AEC (architecture, engineering and construction) industry”.

He said, “We’ve taken that to the next level. We’re going to be introducing this thing called the i-model hub, which allows for data to flow from discipline to discipline, and different hierarchies.”

He said there were different levels of detail.

“The hub can filter out the information depending on what your role is, and what your discipline is. It also manages change – which is huge – it’s communicating and constantly keeping that model up to date.”

This communication can be with the products of other companies, too.

“We believe in third party interoperability,” said Das.

The daily visualisation of a jobsite can help minimise construction delays, prevent clashes between the work onsite and the design, eliminate the need for rework, facilitate stakeholder communication and align schedules.

The Pix4D Crane Camera claims to combine hardware and software to help with this. A camera is mounted on a tower crane jib, from where it captures site images. These are transmitted wirelessly to the Pix4D cloud, and processed automatically to be converted into 2D maps and 3D models.

The company behind it said it was designed to monitor any type of construction, and had already been endorsed by some large companies worldwide.

Early adopter

A metro line project in western France was among the early adopters. Dodin Campenon Bernard, part of the Vinci group, was awarded a 14km project that included a tunnel and underground stations.

The station to be monitored was in the heart of the city centre and made drone flights, which was one option, impossible.

At 32m of digging depth and with massive brace frames to support the excavation, the building site was said to be a challenge. However, through the data collected with the crane camera, Dodin Campenon Bernard was able to follow the evolution of the site day by day.

Romain Nicolas, deputy technical director at Dodin Campenon Bernard, said, “Projects are complicated – unforeseen circumstances can happen and delay the project. This kind of projects take a few years to achieve, and meanwhile, can highly perturb the neighbourhood.”

He said it was crucial to communicate progress on the construction site, and share visual updates from the site to local residents and all stakeholders.

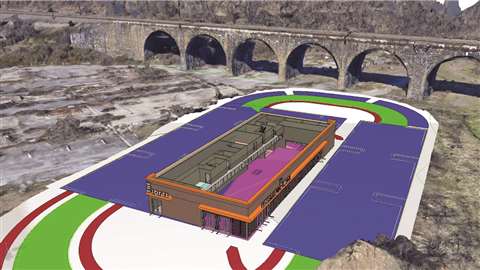

In Zurich, Switzerland, it was a railway bridge that was the focus for Pix4D. The capacity of the Zurich rail network and surrounding region was felt to have reached its limit, and Porr Suisse, part of one of the largest Austrian construction groups, was given the job of expanding the railway infrastructure. This included the construction of a 200m bridge and a new track.

Swiss company BSF Swissphoto was in charge of surveying the infrastructure. It used the crane camera to document the current situation of the site, capturing data daily.

The weekly work progress reports produced were said to have improved communication and collaboration between the companies and subcontractors involved.

A large new hospital complex being built in Denmark covers more than 150,000m2, and had 13 cranes erected.

Pix4D said that with BIM and digital construction technologies, this project was a perfect example of a connected site. The contractors have been continually testing new technologies, and selected the crane camera to be a part of the project.

The results were said to have quickly revealed to be a huge time saver for the project team. Although the project team was based on the work site, the camera was situated on the other side of the site, meaning a long walk to check the building status, which could take a few hours. With a permanent monitoring solution like the crane camera, data has been automatically available when needed, enabling the project team to get information quickly, and make faster decisions when it came to confirming or realigning the schedule.

Pix4D said that combining crane camera use with drones could ensure the most complete aerial site overview, from the earliest earthwork stages of a project.

Unmanned

Drones go under several aliases – UAS (unmanned aircraft system) and UAV (unmanned aerial vehicle), for example.

Trimble is collaborating with Propeller Aero to distribute its UAS analytics platform. Propeller, based in Australia and the US, said it was a leader in the advanced collection, visualisation and analysis of data from drones.

Trimble said Propeller’s simple automated ground control targets, cloud-based visualisation and rapid analysis platform would also be integrated with Trimble Connected Site solutions to bring “an end-to-end cloud-based UAS solution to civil engineering and construction contractors”.

It said that pairing Propeller’s web-based interface with Trimble Connected Site solutions would allow users to unlock the full value of UAS information.

Users can get access to simple tools to measure surface geometry, track trends and changes across time, and perform visual inspections. Trimble said that both technical and non-technical professionals were now able to gather insights remotely and collaborate. It added this would drive improvements in safety and efficiency as well as reducing environmental impact across a construction worksite.

Scott Crozier, director of marketing for Trimble Civil Engineering & Construction, said, “Propeller combines ease of use with powerful analysis tools that allow users to view 2D and 3D deliverables and extract valuable information.

“Like Trimble, Propeller understands the value of quality and accurate data for integration with civil engineering and construction workflows.”

Rory San Miguel, CEO of Propeller Aero, said, “We pride ourselves in taking the most trusted, technical data and tools, and wrapping that up in an easy-to-use online platform that is relevant to the entire organisation, not just technical users.

“Integrating our platform into Trimble’s Connected Site solutions will bring a new class of information to construction sites and organisations globally.”

Also working with UAVs, Texo Drone Survey & Inspection (DSI) said that with UAVs, a big part of keeping on top of potential challenges involved talking to clients ahead of them encountering particular issues, and developing bespoke platforms that mee their needs precisely, by engineering solutions from the bottom up.

It said it had been investing in technology that allowed for heavier payloads and enabling its fleet of UAVs to operate under more difficult weather conditions.

The UAVs currently in operation can deal with wind speeds of up to 15m/s, with the flexibility to carry a variety of custom payloads. Texo DSI has permits for operations up to 20kg, which it said was a game changer for the construction sector.

The company said that a standard LiDAR survey, accuracy of data is generally to around 40mm. However, it claimed that through investment and development of its LiDAR UAV fleet and associated survey software, it was achieving accuracy of 1 to 3mm with its survey grade UAV integrated LiDAR system. This system is delivered via a custom-built UAV platform that measures over 1 million points per second.

Topcon Positioning Group has added advanced connectivity options to its DS-200i direct aiming imaging station.

The DS-200i, now with wi-fi access, provides real-time, touchscreen video and photo imaging to capture measured positions.

Ray Kerwin, director of global surveying products, said, “The ultra-wide 5 MP on-board camera provides photo documentation in the field and can now transmit live video using either LongLink or high-speed WLAN as an access point, which allows the FC-5000 or Windows 10 tablets easily to connect.

“The addition of Wi-Fi connectivity offers convenience to the powerful video capabilities of the DS-200i. The system allows for non-prism measurements to be aimed and measured to remote objects – saving time without having to return to the tripod.”

He added, “The live video allows a remote user to know exactly what is being measured.”

Additional standard features include Hybrid Positioning functionality, Xpointing technology for quick and reliable prism acquisition, TSshield telematics security and maintenance technology, and a rating of IP65 for water-resistant construction.

GNSS suported

Leica Geosystems has just released Leica Spider v7.0 software suite, which is now said to support all GNSS (global navigation satellite systems) – GPS, GLONASS, BeiDou, Galileo and QZSS, as well as the GPS-L5 signal for improved network RTK (real time kinematic) correction services.

The all-in-one solution is said to offer users working on surveying and mapping, among other tasks, improved positioning accuracy and correction service. Leica said that professionals could now increase productivity while they operated reliably in environments with obstructions, like urban canyons, or at high latitudes, thanks to the higher number of usable satellites from multiple GNSS constellations.

Leica said that for the first time, all important GNSS network information was available in one “convenient and easy-to-access web user interface”. The Leica Spider Business Centre web portal is said to combine all the elements to operate the infrastructure efficiently, including user and access management, and network and rover status monitoring.

Markus Roland, product manager for GNSS Networks and Reference Stations, said, “Our goal with this new version is to incorporate the latest developments into our solution to continue our history of pioneering in GNSS.

“We strive to deliver reliable productivity improvements for our customers. With the new Spider v7.0, customer benefits are tangible and quality is ensured.”

Another new surveying technology which is increasingly apparent on jobsites is augmented and virtual reality (AR and VR).

In the UK, Scotland’s University of Strathclyde’s Advanced Forming Research Centre (AFRC) and the Advanced Manufacturing Research Centre with Boeing (AMRC) in Sheffield, South Yorkshire, have been working with Glasgow-based design visualisation company Soluis Group and modular building designer and manufacturer Carbon Dynamic.

Together, they claim to have successfully built a demonstrator for the use of AR and VR in the construction industry.

The technology was first trialled on a 2.2m plasterboard wall which, when viewed with a Microsoft HoloLens, showed a 3D rendering of the plumbing and wiring behind the façade.

The system can also be used to examine different wall parts to ensure there are no gaps in insulation before being sent to a construction site.

David Grant, partnership development leader at the AFRC, said, “This new technology has a role to play before, during and after construction of both domestic and commercial properties.”

He said that before work starts, those involved in a construction project would be able accurately to visualise and walk through a building before the foundations were even dug. He said this would help in identifying any potential issues before they occur.

And a Danish BIM-software company is claiming that for the first time, construction workers will be able to see a mix of reality and digital drawings from their smartphone

Dalux has launched what it says is the world’s first AR technology that works on mobile devices, and shows a mix of construction drawings and reality – based on what is being looked at and the location.

Jakob Andreas Bærentzen, associate professor at the Danish Technical University Compute, said he was impressed that an AR product was mature enough to aid in the construction industry already.

He said, “Dalux’s AR-technology already seems to be useful in practice. This is several years earlier than I expected we would see such solutions.

“It makes the accomplishment even more impressive that the software can handle large amounts of data and is mature for practical use on mobile devices – that are not designed for such tasks in the construction industry as the HoloLens is.”

Dalux co-founder Bent Dalgaard said, “Now, at most large construction projects, a digital BIM model is often created. We can access these drawings through mobile devices, based on the construction worker’s location, and show it as AR.

“The fact that the technology can be used on mobile devices makes the adoption in the construction industry much faster, since everybody has a smartphone or tablet these days, and HoloLens is much more expensive, meaning that not all workers have access to the AR drawings.”

Real-time collaboration

Another company, HoloBuilder, which provides 360° reality capturing of construction sites, is releasing a product featuring new capabilities for real-time collaboration and offline handover for project close-out.

HoloBuilder offers a scalable SaaS (software as a service – licensed on subscription) solution. It is said to be a collection of all features that HoloBuilder offers as a collaborative enterprise package – 360° reality capturing with the JobWalk mobile app, TimeTravel for progress documentation, the measurement tool to measure within 360° images, and annotations.

The company said that users could now collaborate with the whole team and enjoy enterprise level service and security. HoloBuilder lets entire construction project teams contribute to the documentation process.

During project close-out, the project can be downloaded and saved as a view-only deliverable for the owner to keep throughout the lifetime of the building.