3D printer in Amsterdam

14 June 2016

What is claimed to be the world’s first 3D Builder – a 3D printer – has been put into service at FabCity, a temporary sustainable campus at the end of Java Island in Amsterdam, the Netherlands, by Dutch contractor Bam and Universe Architecture.

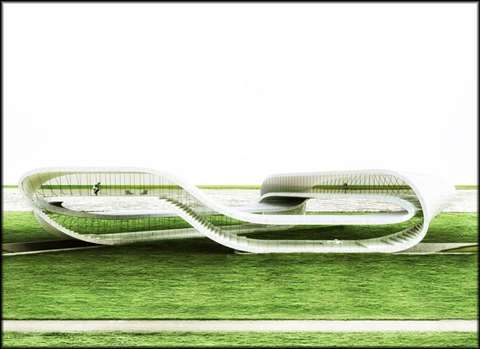

It will construct a Landscape House, a structure based on a Möbius strip, part of a project which is a collaboration between the two companies.

Bam said the building machine was the first of its kind where free-form print technology was linked to automotive industry robotics. It described it as a ground-breaking innovation that made free-form architecture possible, as well as the creation of complex ornamental exteriors.

The new robot with an exchangeable print head can print stone and concrete using the Italian D-shape method. Bam added that in the future, it would be possible to link new print techniques for steel and insulation material. It said that tracks could be placed under the robot – in collaboration with robotics partner AcoTech from Eindhoven – to enable it to travel autonomously across the building site.

The 3D Builder is starting with the construction of the Landscape House on a scale of 1:4 at FabCity.

In 2013, architect Janjaap Ruijssenaars of Universe Architecture announced the creation of “a building without beginning or end” – the Landscape House – using a 3D printer.

The first phase of the project was a 3D printed version, at a scale of 1:15, presented as a city bench in Amsterdam at the end of 2015. The next phase is the FabCity structure, which will be followed by a full-sized house in 2017.

Ruijssenaars said, “It is fantastic that we have jointly conceived a machine that can make something new. This was much more commonplace for architects during the Renaissance.”

Rutger Sypkens of Bam Bouw en Techniek added, “As well as the form freedom, we are also very much taken by the circular process. Concrete granulate and pre-existing prints can serve as a raw material for the machine at a later stage.”

Bam described the method as being comparable to that of an inkjet printer. Instead of putting ink on paper, a bonding liquid is dripped layer by layer on sand that then hardens in any shape as desired. It said the materials now being used in Amsterdam occurred naturally, and had been used by the Chinese many centuries ago for strengthening the Great Wall of China, for example, and by the Romans.

At FabCity, there are 50 pavilions, workshops, installations and prototypes on display, with sustainability and the circular economy as key features. FabCity is open until 26 June, 2016.