Five big offshore lifting projects

21 November 2022

Offshore lifting is getting bigger, heavier, and more complicated. Niamh Marriott reports.

Eager.one’s lifting beam for the vessel Gulliver

Eager.one’s lifting beam for the vessel Gulliver

Big projects are surfacing across the world’s seas as countries seek energy sourced from both traditional and sustainable technologies offshore.

Here are the highlights of offshore projects from around the world, the latest news and the biggest lifts.

1. Gulliver crane begins lift at Hinkley Point C

A firm favourite to start with is Gulliver, the first of two huge offshore cranes, which arrived off the Hinkley Point site in the southwest of the UK earlier this year, to start the lifting programme for the new nuclear power station’s cooling-water system.

Heavy lift contractors, Belgium-based Scaldis, has said that the vessel has a lifting capacity of 4000 tonnes and a maximum lift height of 78.5m above deck.

2. Floating offshore crane

The lifting continued throughout the summer at Hinkley Point C before the arrival of the second floating offshore vessel, Rambiz. The site was getting ready for another engineering feat with the precision placement of 5,000 tonne cooling-water intakes on the seabed.

Four times longer and twice as high as a double-decker bus, each intake head is connected to five miles of tunnels used to circulate cooling-water for the new power station.

Ian Beaumont, project director for marine civils at Hinkley Point C, said, “The successful installation of all six marine heads completes a summer of complex offshore operations in the most challenging of environments.

“Not only is it a significant milestone for the Hinkley Point C project, it also represents an incredible feat of engineering by the teams that have worked in close collaboration to design, construct and place with such precision these massive structures.”

3. Huisman begins work on 3,000 tonne capacity electric crane

In other big news, Dutch crane and heavy engineering specialist Huisman has started work to produce a 3,000 tonne capacity crane for Denmark’s BMS Heavy Cranes.

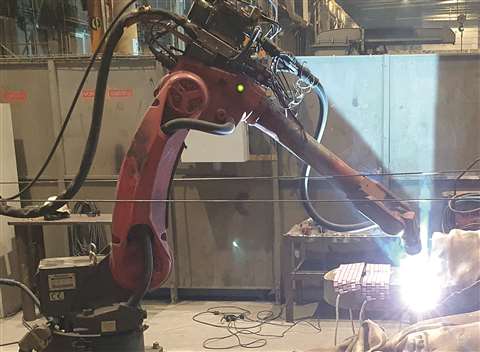

For a heavy crane order, Huisman marked the start by welding pieces of S690 grade steel together using a robotic system. (Photo: Huisman)

For a heavy crane order, Huisman marked the start by welding pieces of S690 grade steel together using a robotic system. (Photo: Huisman)

BMS signed up for the new giant in January 2022. A primary application for the crane will be to help load offshore wind turbine components onto foundations and offshore vessels.

The first two pieces, of S690 grade steel, were welded together using a robotic system.

Huisman also uses wire and arc additive manufacturing (WAAM), to make some components, including hook blocks.

It is basically a 3D printer that works by building up layers of weld.

Using this method mid-size to large components, with complicated shape, can be produced from high tensile steel.

A major benefit of 3D printing, Huisman says, is it significantly reduces delivery time at a price to compete with forgings and castings. Quality is also consistently high, Huisman says.

Delivery of the crane is scheduled for the second half of 2023. The fully electric crane will be able to lift 1,200 tonne components to a height of 225 metres. Loads up to 3,000 tonnes will be handled but at reduced height.

4. Leg encircling crane built for offshore wind projects

Huisman is building a leg encircling crane for the new build F-class jack-up vessel Cadeler. (Photo: Huisman)

Huisman is building a leg encircling crane for the new build F-class jack-up vessel Cadeler. (Photo: Huisman)

Huisman has also announced a contract award from COSCO Shipping Offshore for the design and construction of a leg encircling crane (LEC).

It will be installed on the new-build F-class jack-up vessel of Cadeler, a key supplier in the offshore wind industry for installation services, operations and maintenance works.

The contract award follows last year’s contracts for two identical 2,600 tonne LECs for Cadeler’s X-class vessels.

With this crane, Cadeler will be capable of installing foundations and wind turbines for next generation offshore wind projects worldwide.

The F-class vessel features a unique design, allowing the vessel to convert from being a foundation installation unit to a wind turbine generator installation vessel within a short period of time.

Huisman has designed its LECs to meet the requirements of the continually developing offshore renewables sector.

Seaway 7 has awarded Huisman a contract for a 3,000 tonne spreader bar. It will support installation of offshore wind turbines and is able to handle monopiles with the largest diameter and length currently available.

5. Electric offshore lifting equipment for the wind sector

Liebherr is continuing to develop for the offshore industry, and to meet increasing size demands. Its heavy lift crane series is being expanded with an 800 tonne capacity crane.

The aim with the new crane is to establish itself in the growth market of ever larger wind industry components.

The crane is fully electrically powered and thus enables a reduction of carbon dioxide emissions on the ship side in scenarios that are typical for heavy lift vessels.

The crane manufacturer’s portfolio of port and transshipment solutions has also been expanded to include the all-electric trans-shipment crane CBG 500 E.

Liebherr’s all-electric transshipment crane CBG 500 E. (Photo: Liebherr)

Liebherr’s all-electric transshipment crane CBG 500 E. (Photo: Liebherr)

The crane combines the latest drive technologies with Liebherr’s own crane control system – Master V. Another highlight is the energy recovery system LiCaTronic, which is designed to make optimum use of the energy available.

The numerous configurations ensure the crane is versatile and adaptable to different customer needs, Liebherr says.

With the CBG 500 E, Liebherr says it has designed and developed a crane that can be flexibly adapted to its subsequent purpose.

The crane can be configured with 43 metre and 50 metre boom length.

The longer boom variant offers the decisive advantage of enabling direct transhipment between two vessels in sheltered and open water.

The modes of operation range from bulk to container handling and are independent of the area of operation. For installation on a barge, the crane can be equipped with additional counterweights, enabling safe cargo handling in this application as well.

Optional configuration options such as a comfort ascent or additional platforms and boom walkways for maintenance purposes complete the configuration possibilities.