Roll Group adds high capacity gantry lifting system

06 April 2023

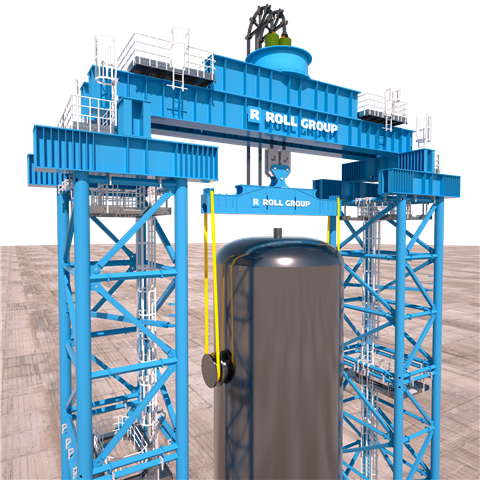

Detail of the head of the new super heavy lift gantry tower system. Image: Roll Group

Detail of the head of the new super heavy lift gantry tower system. Image: Roll Group

Netherlands headquartered Roll Group has added a super heavy lift gantry tower system to its fleet.

At the time of writing it was at the fabrication stage and due to be operational in the middle of 2023. Existing strand jacks from the Roll Lift fleet will provide the lifting muscle for the in-house designed system.

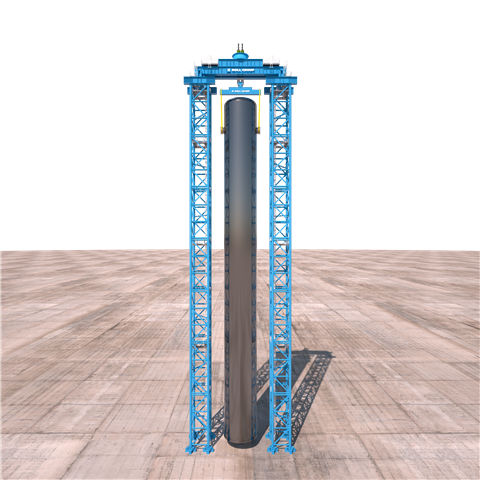

Capacity varies depending on the height but the company has targeted being able to lift 2,400 tonnes to a height of 100 metres, without guy wires. Components of the system can be combined to produce multiple configurations of height, width, capacity, and shape to suit all sorts of heavy lifting applications. Capacity will be greater than 2,400 tonnes at lower height and less than this at heights above 100 metres.

Commenting on the new system Peter Rondhuis, Roll Group CEO, said, “With this gantry system we can further grow in the heavy lift industry as this system will allow us to enter the market of the bigger land-based projects as the gantries are often combined with crane and SPMT scopes.

“Besides this, Roll Group can offer a full factory-to-foundation solution by combining our fleet of heavy transport vessels, SPMTs, cranes and gantry systems. This reduces overall risks for our clients and provides a single point of contact for the whole operation.”

Current capabilities

At this stage enough components are being made to assemble towers 100 metres tall but extra mast sections can be added later. The current maximum span is 23 metres but this can be increased by adding more header beam sections in future. The system components are being fabricated in Singapore, Indonesia and Thailand and will be verified by Lloyd’s in design, fabrication and testing, Roll Group explained.

Its first project is in the petrochemical industry for the installation of tall reactors. In the renewable energy sector the system can be of use in the integration of jackets or for the load out of floating offshore wind farm components. It is also ideal for the installation of goliath cranes, Roll Group said.

An assist crane is used to assemble the tower. That same crane can then be used for tailing the vessel during the main lift.

Ground preparation for the base is extremely important to keep the towers stable and to guarantee the safety of the whole system, the company said. This means the towers need to be supported by a piled concrete foundation, specifically designed for the loads.

Enough components have been ordered to build a system to lift 2,400 tonne components to a height of 100 metres. Image: Roll Group

Enough components have been ordered to build a system to lift 2,400 tonne components to a height of 100 metres. Image: Roll Group