The increasing affordability of electric construction equipment

08 December 2023

There’s no question that battery-powered equipment is gaining momentum and seeing more adoption, but there’s still a steep cost differential over traditional engine-powered machines and that’s a challenge many rental companies need to overcome before getting on board with the trend. But acquisition cost is not the whole story.

Demand for electric machines is expected to continue increasing as equipment buyers realize the long-term lower cost of ownership.

Demand for electric machines is expected to continue increasing as equipment buyers realize the long-term lower cost of ownership.

Major rental firms are leading the charge in bringing electric machines to the market, putting in orders for thousands of battery-powered machines, some of which would traditionally have been diesel powered.

In 2022, France-based Loxam secured a €130m ‘green loan’ from the European Investment Bank on the basis that it plans to spend between 25% and 50% of company CapEx on electric and ‘low emissions’ equipment.

France-based rental firm Kiloutou has pledged that by 2030, around 40% of its fleet will be made up of ‘carbon-free’ vehicles.

And in June, Netherlands-based Boels Rental reported that 80% of its rental fleet of 840,000 items is now electrically powered.

However, so far much of that investment appears to have been spent on low-risk, high-volume items such as scissor lifts, which have always been predominantly battery powered.

Sunbelt Rentals, part of the Ashtead Group, which has operations across the US and in the UK says that it is following a strategy of heavily investing in electric equipment where it sees highest customer demand, especially electric-powered access, battery energy storage units, solar and battery powered tower lights, and other plant.

“We collaborate with our suppliers, customers and partners to assess the benefits, costs and supply and demand for the equipment,” says Andrew Winlow, director of asset management at Sunbelt Rentals UK and Ireland.

Electric vehicles are gaining momentum

According to research company EV Volumes, sales of battery-powered electric vehicles (BEV) and plug-in hybrid electric vehicles (PHEV) accounted for 14.1% of global light vehicle sales in the first half of 2023, up from 11.3% in the same period a year earlier. The researchers predict that, by the end of 2023, global BEV sales will reach 14 million cars – an increase of 33% over 2022 and meaning there will be 40 million EVs in operation.

Moreover, increasing competition in the auto market is prompting car manufacturers to cut prices for some EV models, bringing them more into line with ICE equivalents, especially when government incentives are taken into account.

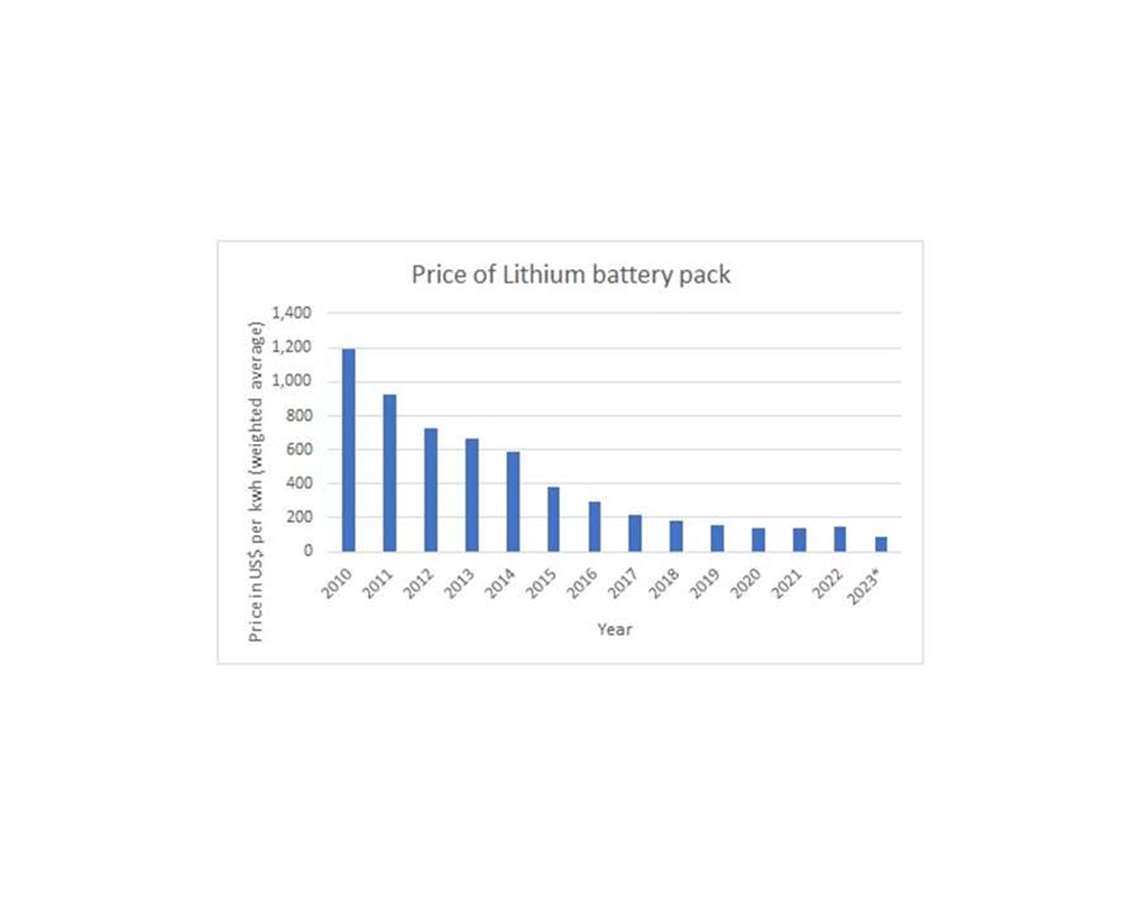

And falling raw materials prices are also helping to push down the cost of lithium-ion battery packs – one of the biggest components of both electric cars and battery-powered construction

equipment – which could help manufacturers market EVs at more competitive prices.

According to energy analytics firm Benchmark Mineral Intelligence, which tracks the cost of battery components, the price of Li-ion battery cells fell below US$100/kWh in August 2023, a 33% drop from March 2022.

German consultancy Roland Berger expects that off road OEMs will ramp up EV production over the next two years and beyond.

It predicts that by 2025, battery-powered mini excavators will account for up to 20% of all new mini excavators produced in Japan and up to 15% of all of those produced in Europe and China. By 2030, it says they will account for up to 35% of the European market and up to 30% of the Japanese market.

Chris Sleight, managing director of Off-Highway Reasearch, estimates the number of battery-powered mini excavators sold in Europe in 2023 accounts for “significantly fewer” than 1,000 machines – at best 0.5% of the European mini excavator market.

By contrast, in the global mainstream auto market, electric vehicle (EV) sales are already entering the mainstream with many analysts expecting to reach a “tipping point” where EV sales outnumber internal combustion sales (ICE) sales sometime after 2025.

How much of a premium does electric equipment carry?

Winlow says Sunbelt is prepared to pay a premium of up to a quarter more for emissions-free equipment in order to drive forward development in the market.

“As early adoptors of electric products, we’re committed to leading the way by providing our customers and partners with sustainable hire solutions. In doing so, we currently pay a premium for electric machines and products that is over 25% compared to what we would pay for their ICE equivalents,” he says.

“We believe our customers and partners can help us reduce this premium by committing to utilize the sustainable equipment and solutions. With government support, rising demand and volume in the sector, as well as OEMs’ support to reduce the costs associated with this equipment by lowering their expectations for R&D payback, will further drive down the price. This in turn will allow us to increase our capital investment to meet demand.”

Winlow notes that prices for electric telehandlers, solar lighting and eco cabins have already “significantly improved” and says that over the coming decade, Sunbelt expects EV construction equipment costs to continue to fall as production ramps up, technology improves and as governments around the world take stronger action to promote a switch over.

“The affordability of small electric machinery today, such as electric telehandlers, solar lighting and eco cabins, has significantly improved,” Winlow says.

“Even if the initial cost of hire or investment remains higher in 2023, we predict that the difference in price between electric and diesel equipment will decrease in the next five to 10 years. Additionally, the implementation of a carbon tax in the UK or Europe, or an increase in customers’ demand for green equipment will further accelerate the affordability of electric equipment with non-electric, reaching parity even sooner.”

Others point out that even without significant falls in purchase prices, electric machines are still becoming more affordable overall, due to their lower fuel and maintenance costs.

Will electric construction equipment become cheaper?

Tate Fencing’s new JCB electric teletruk. (Photo: JCB)

Tate Fencing’s new JCB electric teletruk. (Photo: JCB)

“I think the purchase price of battery mini excavators will always be more than the diesel equivalent,” says Off-Highway Research’s Sleight. “The argument is more around total cost of ownership, which is where electric machines will be more cost effective.”

Mark Ashdown, transport manager fencing and installation specialist at UK-based Tate Fencing, says he has no regrets about his recent purchase of a JCB JCB35-22E electric rough-terrain truck with long telescopic boom for £58,750 (US$74,000), nearly 15% more than the closest diesel alternatives, which retailed at around £51,250 (US$65,000). He says he “would be surprised” if the prices for electric construction machinery come down considerably.

“We try to look at it in terms of cost per hour, which makes it a bit more palatable,” Ashdown says.

Ashdown estimates that with the price of diesel costing between £4 and £4.20 ($4.98-$5.23) an hour and the cost of electricity running at less than £2 an hour and combined with a lower cost of servicing, the higher initial cost will eventually balance out.

For a machine which regularly trucks between an onsite processing plant and a warehouse, clocking up between 10 and 30 hours a week, Ashdown estimates this could take between six and seven years.

Likewise, he reckons the battery-powered JCB will not need replacing for at least seven years, by which time the secondhand market for electric machines should have matured enough to make it relatively easy to sell.

“We think in six- or seven-years’ time a lot of companies will want to make the switch to electric,” Ashdown says. “At that point it might be time to sell this on to the next owner or trade it in and buy a replacement.”

In any case, price is not the only driving factor in Ashdown’s purchasing decision.

“As a business of our size, cost wasn’t actually the main consideration,” he says. “Of course, cost is important, but the overriding consideration was buying a machine that could be used in a warehouse setting without producing emissions which could harm the health and safety of our staff.

“Without an electric machine we would have had to move the loads to a pallet truck which creates extra handling difficulties and extra machinery,” he adds.

Yet, despite Ashdown’s clear optimism in the switch to electrification, at the moment buyers like him are so far very much in the minority.