Peri renovation at Ulm

12 November 2019

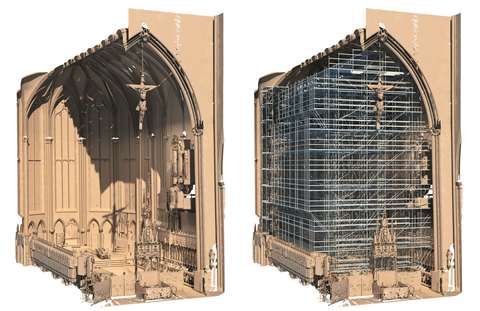

The 161.53m high main tower of Ulm Minster, Germany, is known as the highest church spire in the world – equally as impressive is the 29m long, 15m wide and 26m high choir area.

Peri Systems is assisting with the extensive renovation work on the vaulted ceiling and the choir stalls as part of the restoration of the main tower and the north east, 86m high choir tower.

The ongoing, time-intensive renovation work on the largest evangelical church in Germany started in 2015. In parallel to the main tower restoration to the exterior of the Minster, the internal choir was also worked on in 2019. In 2021, a new construction site will be set up at the north-east choir tower.

The modular Peri UP scaffold system was the key element to the main tower’s renovation. The scaffold is designed for a massive live load of 15 kN/m². A 7m high heavy-duty platform was also erected on the façade to allow for the professional, temporary storage of heavy stones of up to 1.5 tonnes. However, it was not only stability, but also the regional origin of the scaffold that played a major part in the selection decision of the Minster’s head mason, Michael Hilbert and master craftsman, Andreas Böhm. The central location of the rental park for system units at Peri’s head office in Weißenhorn also offered short transport routes.

The Peri engineers’ on-site support ranged from 3D planning to tests for structural integrity, working hand-in-hand with the Ulm Minster builders, the scaffolding workers from Mack, also locally-based, and the surveying service provider, Moselcopter.

Modern surveying

The missing as-built plans for the interior was an obstacle that the Peri engineers were able to overcome with complex 3D scaffold planning using the BIM methodology. It was possible in the early planning phase to avoid possible collisions with historic construction materials by using 3D laser scanning and then transferring this into a 3D building model. The complicated, three-dimensional geometry of the choir’s interior was worked on using the free-standing, metric system grid Peri UP Flex, in 25cm and 50cm chunks with a total size of 13,000m³.

The flexible Peri UP adaptation for the weight and geometry in the 25cm grid also played a very important part in the main tower’s renovation. The manageable, modular ULS Flex lattice girder allowed for 3m to 9m bridgings of up to 30m high without any pipe coupling connections.

In comparison, the bulky dimensions of one-piece lattice girders would complicate or even prevent the installation. Due to the light weight of the individual system parts, these could be transported using small-goods vehicles – an important factor in the historic building’s renovation.

The internal scaffold in the choir of Ulm Minster is currently being dismantled, with the renovation work now concluded. From 2020 it will be open to visitors again. The 86m high, north east choir tower, which has already been surveyed using a drone from the Rheinland-Palatinate company Moselcopter, will be renovated next.