Wacker Neuson to share battery technology

28 April 2021

In developing the battery technology for its machines, Wacker Neuson has taken a “one for all” approach - one battery, able to used on a number of different machines. Now that philosophy is taking on a new meaning as beginning this fall, the modular, rechargeable construction equipment battery developed by Wacker Neuson will also be compatible with equipment made by the company’s cooperation partner Bomag.

Wacker Neuson is making its battery technology available to Bomag beginning this fall.

Wacker Neuson is making its battery technology available to Bomag beginning this fall.

Customers will benefit from simplified construction site logistics and cost savings when they invest in battery-powered devices, creating strong momentum for the wider adoption of emissions-free equipment on construction sites, Wacker Neuson said.

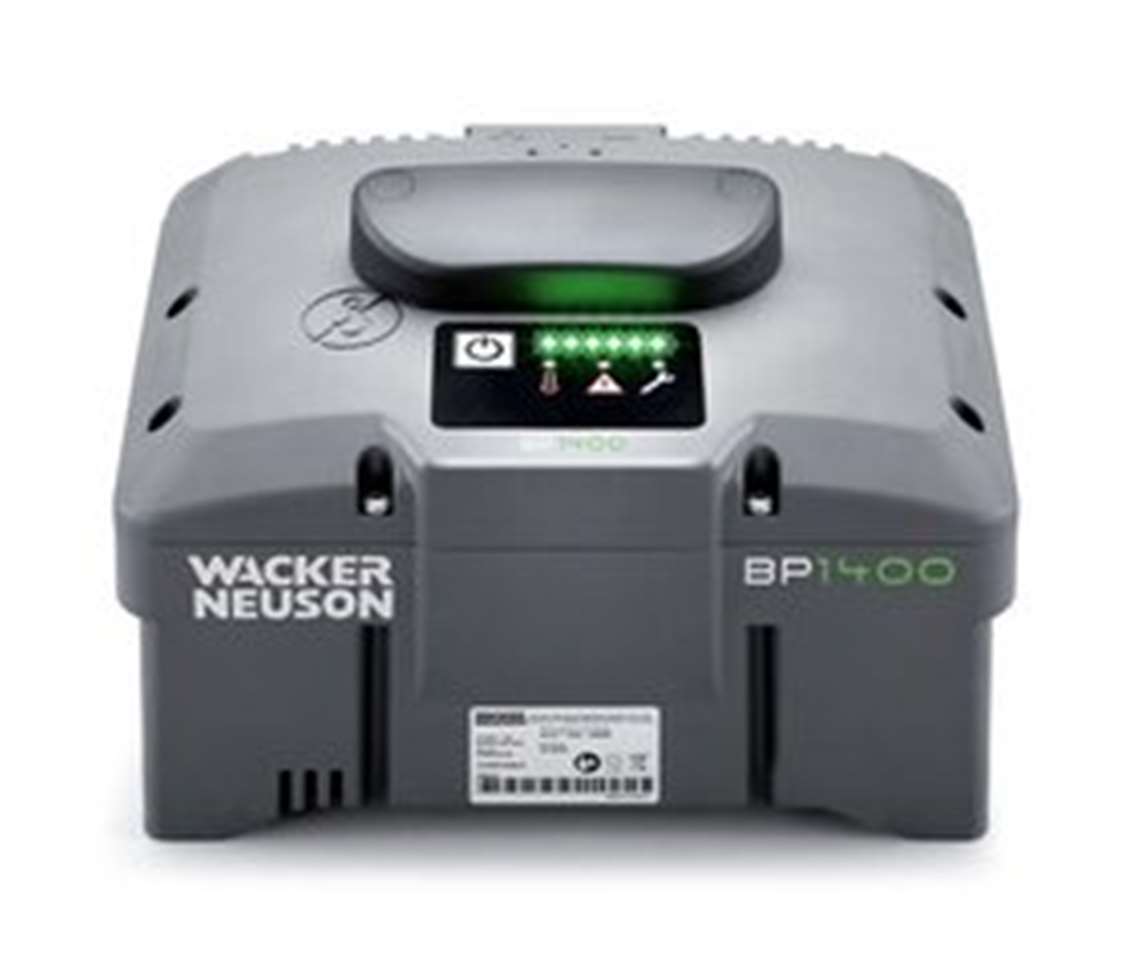

When developing its rechargeable battery, Wacker Neuson said it embraced the “one for all” mindset from the start. This approach enables users to operate different construction equipment products such as rammers and vibratory plates with just one battery. It means that customers only have to invest in one rechargeable battery and charger.

The approach will yield further potential for synergies and savings in the future as the batteries will also be compatible with construction equipment manufactured by Bomag, a competitor in the soil compaction equipment market. “We firmly believe that many more construction sites could be operated without producing any direct exhaust emissions, especially in urban areas,” explained Stefan Pfetsch, managing director of the Wacker Neuson production site in Reichertshofen, the company’s competence center for compaction. “Our interchangeable battery has the potential to power a wide range of construction equipment.

Wacker Neuson’s battery can be used in a range of its rammers and vibratory plates.

Wacker Neuson’s battery can be used in a range of its rammers and vibratory plates.

“By enabling another manufacturer to use our battery, we are further accelerating the adoption of emissions-free construction equipment and underscoring Wacker Neuson’s commitment to fast-tracking carbon reductions.”

Wacker Neuson’s zero emission portfolio includes rammers, vibratory plates and an internal vibrator system as well as electrically powered excavators, wheel and track dumpers and wheel loaders. The company currently offers two interchangeable batteries for construction equipment with power capacities of 1000 Wh and 1400 Wh.