Five tech launches that took Bauma by storm

01 November 2022

From alternative power to digital tools, this year’s show demonstrated the increasing demand for new ways of dealing with modern challenges.

While many look to reduce their emissions, considering the switch to alternative power and finding ways to build efficiently have never been so important. Here are just some of the solutions manufacturers and companies had on offer at this year’s show.

3-in-1 machine control

On its stand at Bauma, Topcon Positioning Systems has shown visitors the latest innovations it has to offer for earthmoving applications, with the launch of the MC-Mobile system.

Described as a 3-in-1 solution that brings machine control to compact equipment, the MC-Mobile system enables construction site operatives to self-perform construction layout, create designs in the field and build to exact specifications and accuracies.

Ulrich Hermanski, CMO and executive vice president for Topcon Positioning Systems, said, “Measurement, design and building with machine control guidance can be accomplished with one system by taking the same tablet display used for measuring, placing it in the cab of the machine, and having a visual to deliver results with unparalleled accuracy.

“This helps contractors be more productive, reducing labour, time, and rework, and therefore increasing profits.”

The MC-Mobile system, which is designed for use on small and medium-sized construction projects, combines surveying and machine control technology and is suitable for use with mini excavators from a range of manufacturers.

It incorporates TS-i4 inertial sensors that measure the machine’s slope and rotation, the MC-X1 machine guidance controller, a wireless Android tablet, a prism with rod for layout and grade checking, and the LN-150 short range layout navigator for 3D optical positioning.

Is data fuel for improvement?

Japanese giant Komatsu displayed its Smart Construction package of solutions at the show and highlighted how digital transformation can increase both the efficiency and productivity of projects.

Smart Construction enables users to remotely gather high-accuracy terrain and machine data from anywhere on a job site to give real-time insight and visualisation of a worksite’s progress.

At the stand, Richard Clement, deputy general manager of Smart Construction, said, “You can only deliver value if you can deliver something that the customer can action and then create further value by doing something.

“You can have fancy technology but if you do not do anything, you do not make a change, then you do not get any value. It is all about putting the technology onto a job site to create the digital twin, to then be able to visualise and analyse what is going on in that digital environment. You want to be able to say to the customer ‘if you did ‘X’ then this is the impact we think you would see’.”

As is often the case, if machines are ordered specifically for certain jobs, the brand and connectivity are not always known beforehand.

“To combat that problem,” says Clement, “We install simple plug-and-play black boxes onto the machines. When a dump truck arrives, it takes you five minutes to get it connected up and live on the system. We can also enable the use of a smartphone-based application to do the data gathering rather than the black box.”

3D printing technology

Formworks and scaffolding manufacturer Peri has exhibited its extensive range of technology at trade show Bauma, including its 3D construction printing platform.

From its 3D printing area at the show, the Germany-based company demonstrated the printing technology - which has already produced the largest 3D-printed apartment building in Europe - to visitors for the first time.

Developed with Danish manufacturer COBOD, the technology has been in development since the last instalment of Bauma in 2019, according to the company.

It uses the COBOD BOD2 gantry printer, said to be the fastest printer available, and enables users to construct more buildings in a shorter period of time.

According to Peri, the use of 3D printing can help the construction industry overcome labour shortages and improve sustainability within the sector.

Primarily aimed at the residential construction and individual prefabricated parts industries, Peri says the technology can “expedite the industrialisation of the construction process” through intelligent designs and an optimised use of materials that the company has added.

Automating the future of construction

ConTech specialist Trimble hosted presentations at a quarry near the fairground, managed by Trimble’s local dealers – TECH Austria, SITECH Deutschland and SITECH Schweiz.

The company demonstrated its latest developments in technology for surveying and machine control at Bauma through live presentations and those who travelled off-site were able to see a fully autonomous roller in action.

Cameron Clark, earthmoving industry director at Trimble Civil Construction, gave us an insight into how autonomy can help, saying, “You’ve got this issue where the experienced people are retiring but there’s still all this demand, there’s the need to be sustainable, and then there are safety regulations.

“We’re focusing on the skills shortage and believe that we can actually solve this dilemma on our path to autonomy.”

The company anticipate the launch of their autonomous system next year. The idea, though, is not to replace operators; Clark emphasised that its role is to increase job-site productivity and efficiency which in turn makes the job easier for those on-site.

At the stand itself, Trimble visitors got a close-up view of the company’s civil construction solutions, including planning and design software, machine control and real-time connectivity.

Alternative drive concepts

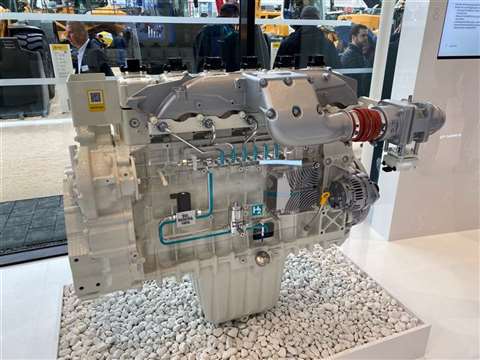

Construction OEM Liebherr unveiled an array of alternative drive concepts within its InnovationLab area.

While the German-Swiss multinational has again brought a huge number of machines to its 15,000m2 outdoor stand, the current and ‘near future’ drives being presented within its InnovationLab proved to be a highlight.

The company says it is pursuing a ‘technology-open’ approach as it drives towards zero-emission powertrains but adds that its strategy will include the future use of the internal combustion engine.

On the stand, Liebherr’s Jurgen Appel described the company’s research into possible alternative drives, saying, “We have machines where battery-electric drive is most suitable and have the best performance, in terms of CO2 emissions.

“But we need to have in our mind, the availability of different energy carriers.”

One of the latest Liebherr advances on display at Bauma is the Liduro Power Port (LPO), a battery-based mobile energy storage system, which allows electrified machines and equipment to be operated or charged locally, with constant power output of up to 120kW.