What are the latest trends in crane simulator training?

14 October 2022

Simulation training offers virtual ‘seat time’ for crane operators looking to hone in on their skills and widen their career prospects in a fluid labor market.

Simulator training provides a competitive edge when it comes to certification and operator skills, while also preventing the wear and tear of equipment. As a win-win tool in a technology driven industry, the future of simulation training is bright. And the return for both operator and contractor, even brighter.

The Vortex Advantage Boom Truck Simulator offers realistic machine behavior.

The Vortex Advantage Boom Truck Simulator offers realistic machine behavior.

ACT gathered a panel of industry experts to weigh in on the trends in this type of training and what the future looks like for heavy machinery and the virtual world. This panel is comprised of Alan Limoges, product manager, CM Labs; John Alexander, director of service, training and telematics, Manitowoc; Mike Wiens, instructor, IUOE Local 115; and Andrew Czarnietzki, lead designer for ITI’s VR Crane product line, and head of ITI’s simulation development team.

Many people in our industry assess that simulation training is only for entry level operators. How can simulation training be used for cross training and advanced skill development?

Limoges: Today’s simulators are data and analytics driven. This means that training techniques can target specific skills deficiencies for cross-training or advanced skill development. In addition, simulators can present trainees with a variety of increasingly challenging scenarios and conditions (lighting, terrain, weather, exercises) that are not always practical or possible with traditional training methods.

CM Labs simulators have the added benefit of enabling advanced crew training exercises for team learning. This might include a scenario with multiple crane operators for tandem lifts, signal person and crane operator communications. Available anytime to safely practice, simulation lends itself to self-paced training, the right formula for self-guided scenarios to continue learning on their own. In today’s fluid labor market, experienced operators are motivated to cross-skill to widen career prospects.

Alexander: Typically, I would agree with this type of training being used for entry-level operators. However, Manitowoc’s new CCS (crane control system) simulators can simulate advanced jobsite scenarios that are beneficial to even advanced operators. Additionally, since our CCS control system is integrated into the simulation scenarios, advanced operators get training on the LMI setup used in our CCS-equipped cranes.

Wiens: As simulators become more advanced and realistic in physics and crane behavior, there are many great ways for training institutions to use them. For example, at the IUOE 115 training association we have specialty created programs created by CM Labs for duty cycle crane work (pile driving, dragline and dredging) and have the availability to take an existing ticketed crane operator with no duty cycle operating experience in their career, and familiarize them with how to safely operate a machine, as well as what is expected of them when operating a crane in a specific duty cycle operation.

Czarnietzki: Simulation can be a powerful tool beyond entry level training. It can be a low-cost alternative for re-certification. It can be an excellent tool for targeted remediation. It can also be an objective source for skill verification. By removing the human factor, operators can be assessed in a more general and objective context, which can help highlight potential deficiencies from complacency, or simply showcase areas for precise targeted improvement.

Cross training is also an excellent use case. Technicians can learn how to operate cranes via the simulator, without needing the full rigor that they would need to become certified operators in the field. These extra skills allow them to perform their job better. Or in the case of upgrading, a simulator provides a way for oilers or other individuals to ‘get seat time’ in a way that might otherwise be impractical. On the advanced side, a simulator can be constructed to create high skill scenarios.

Can simulation training be used for certification testing? What is the stance of regulatory or standards groups about using simulation for skills qualification or certification?

Limoges: Simulators are certainly an effective way to practice for certification testing. A number of CM Labs customers report seeing higher success rates for operators who have practiced for a certification exam on a simulator than those who practiced only on live equipment. The Electrical Training Alliance uses its crane simulator to prepare operators for the certification program through the Electrical Industry Certifications Association. The simulation exercises, inspired by the certification requirements, mirror exact applications, such as auger control, and pole control and setting, rather than generic scenarios. This translates directly into higher success rates as trainees are better prepared for both written and practical exams.

Alexander: Manitowoc’s CCS simulators do have the CCO practical exam which is very beneficial for practicing for the certification exam. Our lattice crawler simulator also offers the emergency laydown simulation which is a requirement for New York City certification.

Wiens: At the simulator’s current standard, no I do not believe we can use it for certification testing. There are too many variables in crane operation that at this time are not able to be captured by a simulator that are critical tasks that operators need to do in order to become certified. As a caveat, I believe that a simulator could be used to help “qualify” an operator in a specialty craning operation through an upgrade program. Examples are an AT crane super lift, crawler super lift, climbing a tower crane, or mobile crane duty cycle crane operator to name a few. Being “qualified” has many different interruptions by different regulatory standards and employers and that also needs to be taken into account.

Czarnietzki: Simulators have a long history with certification, particularly in the aerospace industry. Generally, simulators are seen as an option when real world testing is too costly, complicated or difficult to reliably set up. There are advantages on the simulation side as well: consistency and objectivity. We can know exactly where someone was looking, what someone was doing and ensure they had exactly the same operational context as every other candidate. All that said, making something that is fair and viable for certification is a much steeper process than just creating something that can be used for practice and or orientation.

Manitowoc’s Crane Control Sytem.

Manitowoc’s Crane Control Sytem.

What are the pros/cons differences of different types of simulation platforms, both hardware and software?

Limoges: CM Labs Smart Training Technology and motion-enabled platform provide users with an incredibly realistic experience. CM Labs offers three types of platforms: desktop, motion enabled single-screen and fully immersive up to 5-screen for heavy equipment operator training. The simulator is preloaded with various simulation training packs that can be easily launched while seated. The simulators use real controls, found in industry, that easily swap out.

The desktop version is the least immersive with only one screen and no motion platform, but it is the most transportable. This is good for onsite training or remote needs. All three options use the same proprietary CM Labs’ Vortex software and Smart Training Technology.

Alexander: Our simulation platform is very beneficial to operators due to the integration of our CCS controls. Since we use the same controls/displays, operators can easily move from the simulator to the crane with no additional learning curve.

Wiens: I have only been consistently exposed to one version of a simulator platform and that being CM Labs. I have seen videos and examples of other systems but that is the level of my exposure at this time.

Czarnietzki: For cranes, screens versus VR is a big question. Additionally, motion hardware versus desktop. For cranes especially we feel that the amount of movement is low enough that desktop is generally a viable option, but the 360-degree visibility is so critical to crane operation that VR is a necessity. VR allows for an operator to look naturally, lean their head and see a real-world perspective, as well as have accurate binocular vision.

Some simulators such as a 747-flight simulator, will accurately recreate all the controls and electronics of the vehicle. This allows for extremely precise training but has extreme cost. Similarly, driving a crane via an Xbox controller may communicate some of the core functions but doesn’t transfer well to real world training. Our philosophy has been to find a balance: use generic hardware paired with a realistic VR experience such that we maximize visibility while maintaining sufficient hands-on interaction for the core behaviors.

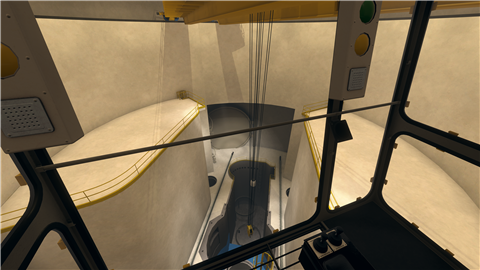

The ITI VR Polar Crane, sometimes referred to as Reactor Servicing Cranes, operate on a circular track or runway, within containment/reactor facilities. Polar cranes’ primary function is removal and replacement of reactor components, and are also utilized during the refueling and outage process.

The ITI VR Polar Crane, sometimes referred to as Reactor Servicing Cranes, operate on a circular track or runway, within containment/reactor facilities. Polar cranes’ primary function is removal and replacement of reactor components, and are also utilized during the refueling and outage process.

What are the differences between AR, VR, Cab/Screen styles and appropriate applications for each?

Limoges: CM Labs simulations are an immersive technology; we do not currently develop augmented reality or VR solutions. We offer three types of platforms: the Vortex Edge Plus desktop, motion-enabled single-screen Vortex Edge Max and fully immersive Vortex Advantage (3- to 5-screen) for heavy equipment operator training. All three use the same proprietary CM Labs’ Vortex software and Smart Training Technology. All platforms use commercially available large screens, making them easily replaceable for ongoing maintenance, and similar to the operator’s natural cab field of view for an as-close-to-immersive experience as possible.

While virtual reality training is an interesting option when trying to offer a fully immersive experience, there are some constraints. Managers lose the ability for actual training with virtual reality. The trainees sit on their own, cut off from the instructor and any teachable moments, without the opportunity to have group discussions.

Alexander: I don’t really have much experience with AR/VR but from what I’ve seen, I don’t think the technology is where it needs to be yet for this to be a good experience for an operator.

Wiens: A work case scenario can be argued for each of these visual interfaces. AR can and is used as an interactive preoperational inspection as an example. VR is an up-and-coming technology and at their current iteration is a viable option to have as the main visual interface on simulators allowing the most immersive experience. The downside is what happens if you need to interact with a side display for the safe operation or the running of a piece of equipment. If you interact with a virtual display, then you lose the tactical nature of interacting and programing a screen.

Cab/Screen style is a valid way to use as a display interface. As the most cost-effective way and potentially (if software supported) can be upgraded to be more immersive then a single screen. The other is the ability to have cab layout and control layout be accurate to the machine type your companies need.

Czarnietzki: AR, like HoloLens, overlays reality. This would be great for an overlay in a location with known points, such as the proof of concept for overlaying parts of an engine or elevator against a real-world object. Generally, these applications run on the headset, and therefore are extremely limited for performance and physical simulation. Field of view is another major limitation. AR augments reality but doesn’t supplant reality, so a solution that minimally adds something to a real-world location is ideal. VR supplants reality. It puts someone in a location and takes over their perspective. When paired with a PC, this can also include high fidelity physics and realism. VR is ideal for putting someone in a cab of a crane on a virtual jobsite. Cab style screen simulators are powerful because each screen can be its own computer, providing a natural point splitting processing load.