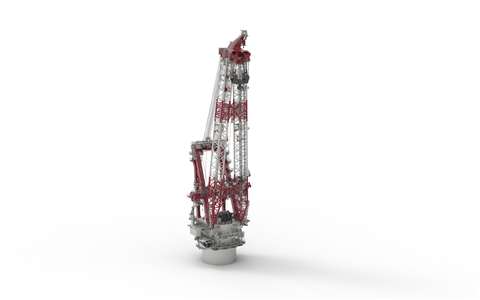

3,000 tonne Liebherr crane takes shape

05 November 2020

A milestone has been reached in construction of the Liebherr Heavy Lift Crane 150000-3000 offshore crane for Alfa Lift.

In Liebherr’s Rostock, north Germany factory, two major components of the new 3,000 tonne capacity wind farm erection crane were assembled in October. The mechanical connection was made between the lower slewing column and the machinery frame to create the lower slewing unit of the HLC.

Liebherr’s customer for this crane is Norwegian specialist contractor OHT. The double lattice boom HLC will be mounted on Alfa Lift, the worlds’ largest and most innovative, custom-built offshore wind foundation installation vessel, Liebherr said. Designed by Ulstein, Alfa Lift is being built in China and is due for delivery in 2021.

HLC 150000-3000 lifts its 3,000 tonnes to a 30 metre radius or 1,000 tonnes at an outreach of 76 metres. With the two major sections of the crane now “married” it is ready for the next stages of assembly. This part of the crane, the machinery frame, contains the electric drive motors, hydraulic pumps and the main switchboards.

OHT worked closely with Liebherr on development of the HLC 150000-3000. Daniel Poll, Liebherr Rostock sales director for ship and offshore cranes, explained, “Both Liebherr and OHT have great confidence in this close partnership, which is the foundation for the multifunctionality of the HLC 150000-3000. An advantage that can be important in this competitive international market.”

Torgeir Ramstad, OHT chief executive officer, commented, “Working in an open and collaborative manner with Liebherr has become an essential element in the development process of Alfa Lift and her onboard equipment. Making sure the operational criteria and limitations of the crane are viewed with a holistic approach, taking into account the vessel’s motion characteristics and capabilities of other mission equipment onboard, is key. Working alongside key suppliers who understand these requirements makes a huge difference in ensuring ultimate success.”

The next milestone in the crane’s construction will be the electrical and hydraulic connection of the two components, followed by connection of the upper and the lower slewing unit.

In addition to installation of offshore wind foundations and sub-stations, HLC cranes are designed to help with installation and decommissioning of offshore platforms.